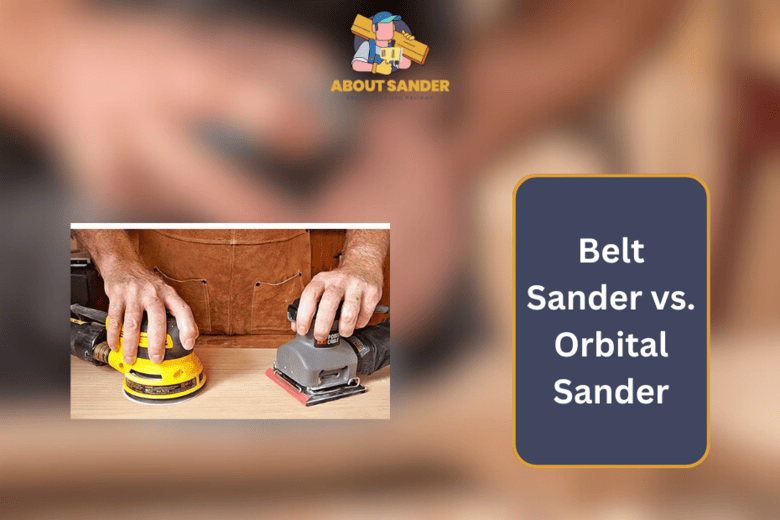

Get clarity on Belt Sander vs Orbital Sander options. Choose the ideal sanding tool for your projects, DIY or professional with our expert comparison.

The debate between belt sander vs orbital sander holds excellent significance in power tools for sanding. This article will explore the key differences and benefits of the belt sander vs orbital sander.

Key Points to Help You Choose Between Belt Sander Vs Orbital Sander

Material Removal Rate:

- If you need to quickly and efficiently remove large amounts of material, especially for heavy-duty tasks like levelling uneven surfaces or stripping paint, choose a belt sander. It excels in high material removal rates, thanks to its robust motor and continuous abrasive belt.

Versatility:

- For versatility in handling various materials such as wood, metal, and concrete, as well as tasks ranging from rough shaping to fine finishing, opt for a belt sander. It’s your go-to tool for a wide range of applications.

Surface Size and Vertical Sanding:

- When working on large surfaces like floors, decks, or tabletops, and when vertical sanding is required for walls or doors, a belt sander with its wider belts and vertical sanding capability provides better coverage, control, and efficiency.

Finish Quality and Precision:

- If achieving a smooth, swirl-free finish is your priority, especially for intricate work or finer surfaces, then the orbital sander is the better choice. Its random orbital motion minimizes visible sanding marks and offers precision.

Noise Level and Maneuverability:

- When working in noise-sensitive environments or needing a lighter, more manoeuvrable tool, the orbital sander stands out. It operates quietly and is generally easier to handle for extended periods, especially on smaller or curved surfaces.

In summary, when deciding between a belt sander and an orbital sander, consider your specific project requirements, material types, and desired finish quality. Both tools have their strengths, and understanding these key differences will help you make an informed choice for your sanding needs.

5 Key Features of Belt Sanders:

Choosing between a belt sander and an orbital sander becomes crucial when sanding surfaces. This portion will focus on belt sanders and delve into their key features, highlighting the differences from orbital sanders. We will explore the efficiency and versatility of belt sanders, including popular models like the Bosch belt sander and Rockwell sander.

1: High Material Removal Rate:

Belt sanders are renowned for their exceptional material removal rate. With their robust motors and continuous abrasive belts, they excel at quickly and efficiently removing large amounts of material. Whether it’s levelling uneven surfaces or stripping layers of paint, belt sanders can easily handle tough sanding jobs. This feature makes them ideal for heavy-duty projects where speed and efficiency are paramount.

2: Versatile Applications:

The versatility of belt sanders is another crucial aspect that sets them apart from orbital sanders. Their aggressive sanding action allows them to tackle various materials, including wood, metal, and concrete. A belt sander machine offers many applications, from rough shaping and sanding to fine finishing. Moreover, it is also helpful in sharpening a knife.

3: Effective on Large Surfaces:

Due to their wider sanding belts and larger sanding area, belt sanders are particularly practical when working on large surfaces. The wider strap allows for more coverage and faster sanding, making them suitable for sanding floors, decks, or tabletops.

The vertical orientation of the sander also provides better control and stability, ensuring consistent results on expansive surfaces. However, because of excessive use, sanding belts become clogged with debris.

4: Compatibility with Vertical Sanding:

One notable advantage of belt sanders is their ability to perform vertical sanding. This feature proves invaluable when working on vertical surfaces like walls or doors. Belt sanders can effortlessly remove paint or smooth out imperfections without causing fatigue, thanks to their design and handle ergonomics. The vertical sanding capability of belt sanders offers greater convenience and efficiency in specific applications.

5: Popular Belt Sander Models:

Several manufacturers, including renowned brands like Bosch and Rockwell, produce reliable, high-performance belt sanders. The Bosch belt sander, known for its durability and precision, offers a wide range of features suitable for professional and DIY use.

Pros :

- The high material removal rate

- Versatility in applications

- Effective on large surfaces

- Compatibility with vertical sanding

- Suitable for heavy-duty sanding tasks

Cons:

- It can be not very nice and may require more skill to avoid over-sanding

- Limited in providing fine finishes

- Prone to leaving visible sanding marks if not used carefully

- Bulkier and heavier compared to orbital sanders

- Potential for belt tracking issues if not properly maintained

5 Key Features of Orbital Sanders:

When it comes to power tools for sanding, choosing between a belt sander and an orbital sander is essential. We will explore orbital sanders’ unique characteristics and advantages, including popular models such as the Bosch belt and Rockwell sander.

1: Random Orbital Motion:

The defining feature of orbital sanders is their random orbital motion. Unlike the linear movement of belt sanders, orbital sanders employ a circular sanding pad that moves in both a rotating and random orbit pattern. This motion reduces the risk of leaving visible sanding marks on the surface, ensuring a smooth and flawless finish.

2: Versatility in Finishing:

Orbital sanders excel in providing excellent finishing capabilities. Their unique sanding motion, combined with the availability of different grit sandpaper, allows for precise and refined finishes on surfaces. Whether preparing wood for staining, sanding between coats of paint, or polishing metal, orbital sanders offer versatility in achieving desired final appearances.

3: Dust Collection System:

Many orbital sanders come equipped with efficient dust collection systems. These systems help minimize the accumulation of dust and debris during sanding, improving visibility and creating a cleaner work environment. Incorporating a dust collection mechanism ensures that particles are effectively captured, reducing the risk of airborne dust and promoting better overall safety.

4: Lightweight and Maneuverable:

Unlike the bulkier belt sanders, orbital sanders are generally lighter and more manoeuvrable. The compact design and ergonomic handles of orbital sanders make them comfortable to hold and operate for extended periods. This feature allows for greater control and precision, especially when working on intricate or curved surfaces.

5: Quieter Operation:

Orbital sanders are known for their relatively quiet operation compared to louder and more powerful belt sanders. This attribute makes orbital sanders more suitable for environments where noise reduction is a concern, such as residential areas or shared workspaces. The quieter operation of orbital sanders adds to their overall user-friendliness and convenience.

Pros:

- Random orbital motion for smoother finishes

- Versatility in achieving satisfactory results

- Efficient dust collection systems

- Lightweight and manoeuvrable

- Quieter operation compared to belt sanders

Cons:

- It may take longer to remove material compared to belt sanders

- Less effective for heavy-duty sanding tasks

- Limited in sanding large surfaces efficiently

- Sanding pads may need frequent replacement

- It can be less aggressive for rapid material removal

A Comprehensive Comparison of Belt Sander vs Orbital Sander:

Choosing between belt sander vs orbital sander is crucial when effectively sanding surfaces. In this comparison, we will explore the key differences between these two power tools, delving into their features and applications. So, let’s dive into the world of belt and orbital sanders, comparing their performance, versatility, usability, and more.

1: Sanding Action:

One of the primary distinctions between belt sanders and orbital sanders lies in their sanding action. Belt sanders utilize a continuous loop of abrasive sandpaper that moves linearly, allowing for fast and aggressive material removal. On the other hand, orbital sanders employ a circular sanding pad that moves in a random orbital motion, providing a finer and swirl-free finish.

2: Material Removal Rate:

With their powerful motors and aggressive sanding action, Belt sanders excel at high material removal rates. They are ideal for tackling heavy-duty tasks such as levelling uneven surfaces or removing layers of paint. While slower in material removal, orbital sanders offer better control and precision, making them suitable for achieving fine finishes on different materials.

3: Versatility:

When it comes to versatility, belt sanders have the upper hand. Their robust design and aggressive sanding action allow them to handle various applications such as shaping wood, smoothing rough surfaces, or removing old finishes. Conversely, orbital sanders are more suited for lighter sanding tasks, intricate work, and achieving smooth finishes.

4: Surface Coverage:

With their wider belts and larger sanding areas, Belt sanders are highly efficient when sanding larger surfaces. They can cover more ground quickly, making them suitable for sanding floors, tabletops, or decks. In contrast, orbital sanders have smaller sanding pads and are better suited for smaller or curved surfaces, offering more excellent manoeuvrability and control.

5: Finish Quality:

When it comes to finishing quality, orbital sanders shine. Their random orbital motion reduces the risk of sanding marks, providing a smoother and more polished result. Due to their aggressive nature, Belt sanders can leave visible sanding marks if not used carefully or with finer grits. Orbital sanders are the preferred choice for achieving finer and more refined finishes.

6: Ease of Use:

Orbital sanders are generally easier to handle and operate compared to belt sanders. They are lighter, more compact, and offer better control, making them suitable for more extended periods of use. Belt sanders, while powerful, can be bulkier and heavier, requiring more physical effort to operate. However, vertical belt sanders like the Bosch belt sander offer enhanced manoeuvrability and ergonomics.

7:Dust Collection:

Both belt and orbital sanders often come equipped with dust collection systems to minimize dust and debris accumulation during sanding. However, orbital sanders typically have more efficient dust collection mechanisms, resulting in cleaner work environments and better visibility. This makes orbital sanders preferred for those who prioritize cleanliness and reduced dust exposure.

8: Noise Level:

Orbital sanders operate at lower noise levels than belt sanders, generally louder due to their more powerful motors. The quieter operation of orbital sanders makes them suitable for use in noise-sensitive environments such as residential areas or shared workspaces.

5 Key Differences: Belt Sander vs Orbital Sander:

Choosing between a belt sander and an orbital sander is crucial when effectively sanding surfaces. This comparison will explore the key differences between these two power tools, exploring their unique features, applications, and performance.

1: Sanding Action:

The primary difference between orbital and belt sanders is their sanding action. Orbital sanders feature a circular sanding pad that moves in a random orbital motion. This motion minimizes the risk of leaving visible sanding marks and ensures a smooth, swirl-free finish.

2: Material Removal Rate:

Belt sanders excel in their material removal rate. With their powerful motors and aggressive sanding action, they can quickly remove significant amounts of material. In contrast, orbital sanders have a slower material removal rate but offer better control and precision, making them suitable for achieving fine finishes on different materials.

3: Versatility:

In terms of versatility, belt sanders have the advantage. Their robust design and aggressive sanding action allow them to handle various applications. On the other hand, orbital sanders are more suitable for lighter sanding tasks, intricate work, and achieving smooth finishes on smaller or curved surfaces.

4: Surface Coverage:

Belt sanders are highly efficient when it comes to sanding larger surfaces. With their wider belts and larger sanding areas, they can cover more ground in a shorter time. In contrast, orbital sanders have smaller sanding pads offering excellent manoeuvrability and control. They are better suited for smaller or curved surfaces that require more precise sanding.

5: Finish Quality:

Orbital sanders are known for delivering superior finish quality. Their random orbital motion reduces the risk of leaving visible sanding marks on the surface, providing a smoother and more polished result. Due to their aggressive nature, Belt sanders can leave noticeable sanding marks if not used carefully or with finer grits.

5 Key Similarities: Belt Sander vs Orbital Sander:

When sanding surfaces effectively, both orbital and belt sanders play essential roles. This comparison will explore the fundamental similarities between these two power tools, focusing on their shared features, applications, and functionalities. So, let’s delve into the world of sanding as we compare their sanding actions, usability, dust collection, versatility, and materials they can handle.

1: Sanding Action:

While orbital and belt sanders have different sanding actions, they aim to remove material and smooth surfaces. Orbital sanders utilize a circular sanding pad that moves randomly, providing a swirl-free finish. On the other hand, Belt sanders use a continuous loop of abrasive sandpaper that moves in a linear motion, allowing for more aggressive material removal.

2: Usability:

Both orbital sanders and belt sanders are user-friendly and relatively easy to operate. They typically feature ergonomic designs, comfortable handles, and intuitive controls that enhance the user experience. While there might be differences in weight and manoeuvrability between specific models, both sanders aim to provide ease of use and efficiency during sanding tasks.

3:Dust Collection:

Both orbital and belt sanders often come equipped with dust collection systems to minimize dust and debris accumulation during sanding. These systems help maintain a clean work environment, improve visibility, and reduce the health risks associated with airborne particles.

4: Versatility:

Both orbital sanders and belt sanders offer versatility in their applications. While belt sanders are known for their ability to handle heavy-duty tasks such as levelling surfaces and removing paint, orbital sanders excel at achieving fine finishes and intricate work. However, both types of sanders can be used on various materials, including wood, metal, plastic, and more.

5: Materials:

Orbital sanders and belt sanders are suitable for sanding various materials. Whether working with wood, metal, or other surfaces, both sanders can effectively remove imperfections, smooth rough spots, and prepare surfaces for further treatment.

FAQs

What is the main difference between a belt sander and an orbital sander?

The main difference lies in their sanding actions. A belt sander uses a continuous loop of abrasive sandpaper that moves linearly, allowing for aggressive material removal. In contrast, an orbital sander features a circular sanding pad that moves randomly, providing a swirl-free finish and better control.

Which type of sander is better for heavy material removal?

For heavy material removal tasks, a belt sander is the preferred choice. Its powerful motor and aggressive sanding action make it efficient in removing significant amounts of material, such as levelling uneven surfaces or stripping layers of paint.

Which sander is more suitable for achieving fine finishes?

When it comes to achieving fine finishes, an orbital sander is the recommended option. Its random orbital motion reduces the risk of leaving visible sanding marks, providing a smoother and more polished result. It is ideal for achieving intricate details and fine finishes on different materials.

Can both sanders be used on various materials?

Yes, belts and orbital sanders can be used on various materials, including wood, metal, and plastic. However, the sander choice depends on the specific material and the desired outcome. Belt sanders are more versatile for heavy-duty tasks, while orbital sanders excel in achieving refined finishes on different surfaces.

Which sander is easier to handle and control?

Orbital sanders are generally easier to handle and control compared to belt sanders. They are lightweight, compact, and offer better manoeuvrability, making them suitable for more extended periods of use. Belt sanders, although powerful, can be bulkier and heavier, requiring more physical effort to operate.

What type of sander is best for floors?

The best type of sander for floors is an orbital sander, which efficiently removes a significant amount of material and provides a smooth finish.

What is a belt sander best used for?

A belt sander is best used for heavy material removal and rough sanding tasks, such as stripping paint or shaping wood surfaces.

Conclusion:

Choosing between a belt sander and an orbital sander can be easier when you have answers to common questions. Understanding the differences in their sanding actions, applications, and suitability for specific tasks is crucial. Whether you prioritize heavy material removal or fine finishes, both belt and orbital sanders have advantages.

Why Trust About Sanders?

When it comes to the world of sanding and sanders, you need a trusted source of information and guidance to ensure you achieve those perfect finishes. That's where I come in – I'm Martin, a dedicated sanding enthusiast with a relentless passion for attaining flawless surfaces. With years of hands-on experience in the sanding industry, I've honed my skills and expertise to provide you with the most reliable and accurate insights. What sets me apart is my commitment to excellence. I meticulously handpick each sander after rigorous testing, ensuring that only the best tools make it to your hands. My goal is to empower you with the knowledge and recommendations you need to tackle any sanding task confidently. When you trust About Sanders, you're putting your faith in a seasoned expert who shares your passion for perfection and strives to deliver top-notch information and reviews for every sanding challenge.