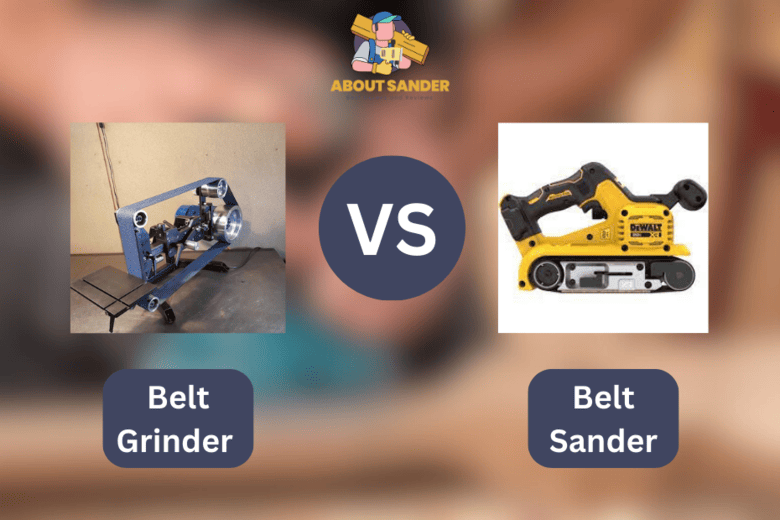

A belt grinder is a heavy-duty tool used for metalworking and shaping, while a belt sander is designed for woodworking and finishing tasks on softer materials.

The battle of the belt grinder vs. belt sander has long intrigued artisans and DIY enthusiasts. These versatile tools share a common purpose of abrasive material removal but differ in design, features, and applications.

Key Takeaways:

- Belt grinders excel in heavy stock removal and shaping tasks, while belt sanders focus on surface preparation and fine sanding.

- Belt grinders and belt sanders have specific purposes and functionalities, and using each tool as intended for optimal results is generally recommended.

- When choosing between a belt grinder and a belt sander, consider the nature of your project, the materials you’re working with, and the desired outcome.

- Understanding the primary differences between these tools will help you make an informed decision and achieve optimal results in your material shaping, grinding, or sanding projects.

Quick Comparison

Here’s a simple comparison table for Belt Grinder vs. Belt Sander:

| Aspect | Belt Grinder | Belt Sander |

|---|---|---|

| Purpose | Metalworking, shaping | Woodworking, finishing |

| Material | Hard metals | Wood, plastics, soft metals |

| Abrasiveness | High | Medium to high |

| Motor Power | High | Moderate to high |

| Precision | Precise material removal | Fine surface smoothing |

| Speed Adjustment | Variable speed control | Variable speed control |

| Contact Area | Narrow, focused grinding | Wide, even sanding |

| Cooling | Often water-cooled | No cooling mechanism |

| Common Use Cases | Knife making, metal shaping | Furniture making, sanding |

| Safety Considerations | Requires careful handling | Requires proper technique |

| Dust Collection | Often minimal | Improved dust extraction |

Please note that specific features and characteristics can vary between different models of belt grinders and belt sanders.

1. Belt grinders

A belt grinder is a powerful and versatile tool designed for material shaping, grinding, and finishing. It features a rotating abrasive belt that moves continuously to remove stock, smooth surfaces, and create precise contours with ease.

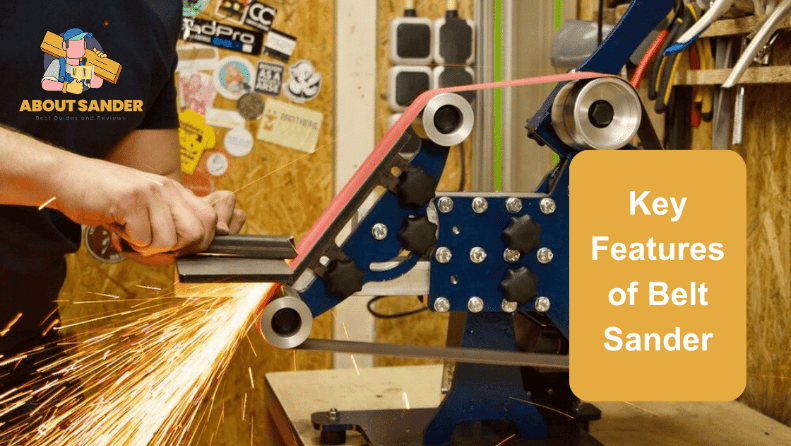

Exploring Key Features of the Belt Grinder

Regarding heavy-duty material shaping and grinding, the belt grinder is a top contender among power tools. With its robust construction and versatile capabilities, the belt grinder offers distinct advantages over its counterparts, like the bench grinder, benchtop sander, and table grinder. In this article, we will delve into the critical features of the belt grinder, highlighting its efficiency, flexibility, and suitability for various applications in metalworking and beyond.

Abrasive Belt System:

The heart and soul of the belt grinder is its abrasive belt system. Typically featuring a 2 x 72 grinder belt, this tool uses a continuous loop of abrasive material that rotates over two or more pulleys. The belt can vary in grit size, allowing precise control over the grinding process. Whether it’s removing excess material, shaping metal, or creating smooth finishes, the abrasive belt system of the belt grinder ensures efficient stock removal and excellent surface preparation.

Adjustable Speed and Versatility:

One notable advantage of the belt grinder is its adjustable speed control, enabling users to adapt the tool’s performance to specific tasks. This versatility is particularly valuable when working with different materials and achieving varying finishes.

Large Work Area and Adjustable Work Rest:

The belt grinder typically offers a larger work area than a typical belt sander for metal or a bench grinder. This spacious work surface allows for better manoeuvrability and visibility, making handling larger or irregularly shaped workpieces easier. Additionally, many belt grinders come with adjustable work rests that can be positioned to support and stabilize the workpiece, ensuring precision and safety during operation.

Attachment Compatibility:

One of the standout features of the belt grinder is its compatibility with a wide range of attachments. These attachments expand the tool’s capabilities, allowing for sharpening blades, hollow grinding, and polishing.

2. Belt sanders

A belt sander is a versatile power tool for sanding and smoothing surfaces. It features a continuous loop of sandpaper that rushes linearly, allowing for efficient material removal and achieving a smooth, even finish. Belt sanders can also be used for sharpening a knife.

Exploring Key Features of the Belt Sander

Regarding sanding and smoothing surfaces, the belt sander is popular among woodworkers, DIY enthusiasts, and artisans. While often compared to its counterpart, the belt grinder, the belt sander offers distinct features and advantages, making it a valuable tool in the workshop.

Continuous Loop Sanding Belt:

The belt sander distinguishes itself with its continuous loop sanding belt, which rapidly moves linearly. This design allows for efficient material removal, making it an ideal tool for tasks that require quick stock removal or levelling of surfaces. The belt sander can handle a range of sandpaper grits, enabling users to achieve desired finishes, from coarse sanding to fine polishing, with ease and precision.

Wide Sanding Area and Ergonomic Design:

The belt sander typically features a wide sanding area, providing ample coverage and allowing for efficient sanding of larger surfaces. This advantage sets it apart from tools like the bench grinder, benchtop sander, and table grinder, which may have more restricted sanding capacities.

Quick Belt Changes and Adjustable Speed:

One notable feature of the belt sander is its quick belt change mechanism. This allows users to easily replace worn-out sanding belts or switch to different grits as needed, minimizing downtime and increasing productivity. Furthermore, many belt sanders offer adjustable speed settings, enabling users to tailor the tool’s performance to specific applications.

Dust Collection System:

Many belt sanders have a dust collection system to maintain a clean and healthy working environment. This feature helps capture and contain the dust and debris generated during sanding, reducing the number of airborne particles and improving visibility.

Belt Grinder vs. Belt Sander: A Comprehensive Comparison

The workshop’s belt grinder and sander are potent material shaping, grinding, and sanding tools. In this article, we will delve into a detailed comparison of the belt grinder vs. belt sander, exploring eight key points that differentiate these tools and help you determine which one is best suited for your needs.

Stock Removal and Shaping:

One of the primary distinctions between the belt grinder and the belt sander lies in their intended applications. The belt grinder excels in heavy stock removal and shaping tasks, making it ideal for projects requiring aggressive material removal and rapid metal shaping, such as blade grinding or forging.

Grit Options and Finishing:

The belt grinder and sander offer different options regarding grit selection and finishing capabilities. Belt grinders typically accommodate various grit sizes, allowing coarse grinding to achieve desired profiles or efficiently remove large amounts of material. In contrast, belt sanders often feature a more comprehensive range of finer grits, enabling users to achieve smoother finishes for final surface preparation or delicate sanding tasks.

Speed and Versatility:

In terms of speed and versatility, both tools have distinct advantages. Belt grinders often feature adjustable speed controls, providing versatility for different applications and materials. This flexibility is beneficial when working with various types of metals that require different grinding speeds for optimal results.

Work Area and Accessibility:

Regarding the work area and accessibility, the belt grinder and sander have notable differences. Belt grinders often have a larger work area, and flexible work rests, allowing for more maneuverability and better support when working with more significant or irregularly shaped workpieces.

Additional Attachments and Accessories:

Both belt grinders and belt sanders offer opportunities for expanded functionality through the use of attachments and accessories. Belt grinders are known for their compatibility with various branches, such as tool rests, sharpening jigs, and contact wheels, which enhance their versatility for specific grinding tasks.

Power and Motor Size:

Due to their different intended applications, belt grinders and sanders often differ in power and motor size. Belt grinders, designed for heavy-duty grinding and shaping, typically have more powerful motors to handle the demanding tasks they are built for. In contrast, belt sanders focused on surface preparation and fine sanding may have slightly less powerful engines that adequately perform their intended applications.

Dust Collection and Safety:

Dust collection and safety are essential considerations in any power tool comparison. Belt grinders and belt sanders may vary in their dust collection capabilities. Belt sanders often have integrated dust collection systems or ports for connecting to external vacuum systems, minimizing airborne dust particles and improving visibility during sanding operations.

Belt Grinder vs. Belt Sander: Highlighting 5 Key Differences

The comparison between the belt grinder and the belt sander reveals distinct differences that make each tool suitable for specific applications in the workshop. In this article, we will focus on five critical differences in the belt grinder vs. belt sander debate, shedding light on the unique characteristics of these tools.

Material Removal and Shaping Capabilities:

One of the primary differences between the belt grinder and the belt sander is their material removal and shaping capabilities. In contrast, belt sanders focus more on surface preparation and fine sanding, offering smooth and even finishes on wood, metal, or other materials.

Grit Options and Finishing Flexibility:

Another notable difference between the belt grinder and sander is their range of grit options and finishing flexibility. Belt grinders typically accommodate various grit sizes, allowing coarse grinding to achieve desired profiles or efficiently remove substantial amounts of material. Conversely, belt sanders often offer a more comprehensive range of finer grits, providing more options for smoother finishes during final surface preparation or delicate sanding tasks.

Speed Control and Versatility:

This flexibility proves advantageous when working with various types of metals that require different grinding speeds for optimal results. On the other hand, belt sanders usually have fixed speed settings, as they are primarily designed for consistent and controlled sanding operations.

Work Area and Accessibility:

Belt grinders tend to have larger work areas and flexible work rests, allowing for improved manoeuvrability and better support when working with more significant or irregularly shaped workpieces. In contrast, belt sanders may have a narrower sanding area, which can be advantageous for precision sanding in tight spaces or working on smaller projects.

Primary Applications and Focus:

Ultimately, the belt grinder and sander have different primary applications and focus areas. Belt grinders are the go-to tools for heavy-duty grinding and shaping tasks, commonly used in metalworking and blade-making industries. On the other hand, belt sanders are primarily geared toward surface preparation and fine sanding, making them popular among woodworkers and those seeking smooth and even finish on various materials.

FAQs

What are the primary differences between a belt grinder and a sander?

While both the belt grinder and the belt sander utilize a continuous loop abrasive belt, their primary differences lie in their intended applications and functionalities. Belt grinders excel in heavy stock removal and rapid shaping tasks, making them suitable for metalworking projects that require aggressive grinding and shaping.

Can a belt grinder be used as a belt sander and vice versa?

A belt grinder’s high power and aggressive grinding capabilities make it unsuitable for delicate sanding tasks typically associated with belt sanders. Similarly, a belt sander’s lower power and fine sanding focus may not provide the necessary material removal and shaping capabilities of a belt grinder.

Which tool should I choose for my specific project needs?

Choosing between a belt grinder and a belt sander depends on the nature of your project and the desired outcome. A belt grinder will be more suitable if you primarily work on heavy stock removal, rapid shaping, or metal grinding tasks.

What is a belt sander best for?

A belt sander is best for smoothing and shaping wood surfaces.

How long do belt sander belts last?

Belt sander belts typically last for two to three years, but the lifespan can vary depending on the material and intensity of use.

Can a belt sander remove paint?

Yes, a belt sander can effectively remove paint from various surfaces, including wood, metal, and plastic.

Conclusion:

In the ongoing debate of belt grinder vs. belt sander, it is clear that these power tools have distinct differences in their capabilities and intended applications. So, explore the unique characteristics of each device and make an informed choice in the belt grinder vs. belt sander comparison to achieve optimal results in your material shaping, grinding, or sanding endeavours.

Why Trust About Sanders?

When it comes to the world of sanding and sanders, you need a trusted source of information and guidance to ensure you achieve those perfect finishes. That's where I come in – I'm Martin, a dedicated sanding enthusiast with a relentless passion for attaining flawless surfaces. With years of hands-on experience in the sanding industry, I've honed my skills and expertise to provide you with the most reliable and accurate insights. What sets me apart is my commitment to excellence. I meticulously handpick each sander after rigorous testing, ensuring that only the best tools make it to your hands. My goal is to empower you with the knowledge and recommendations you need to tackle any sanding task confidently. When you trust About Sanders, you're putting your faith in a seasoned expert who shares your passion for perfection and strives to deliver top-notch information and reviews for every sanding challenge.