Choose the right sander for your needs: pneumatic vs electric Random Orbital Sander. Compare weight, noise, power, portability.

Pneumatic sanders are powered by compressed air, while electric sanders run on electricity. This article will explore the differences between pneumatic and electric random orbital sanders and help you decide which suits your needs.

Pneumatic Vs Electric Random Orbital Sanders

| Features | Pneumatic Random Orbital Sanders | Electric Random Orbital Sanders |

| Power Source | Compressed air | Electricity |

| Size and Weight | Smaller and lighter | Bigger and heavier |

| Noise Level | Louder | Quieter |

| Cost | Less expensive | More expensive |

| Maintenance | Regular oiling and cleaning | Less maintenance required |

| Portability | Requires air compressor | Can be used anywhere with power |

| Durability | Sturdy construction | Susceptible to electrical issues |

What is a Pneumatic sander?

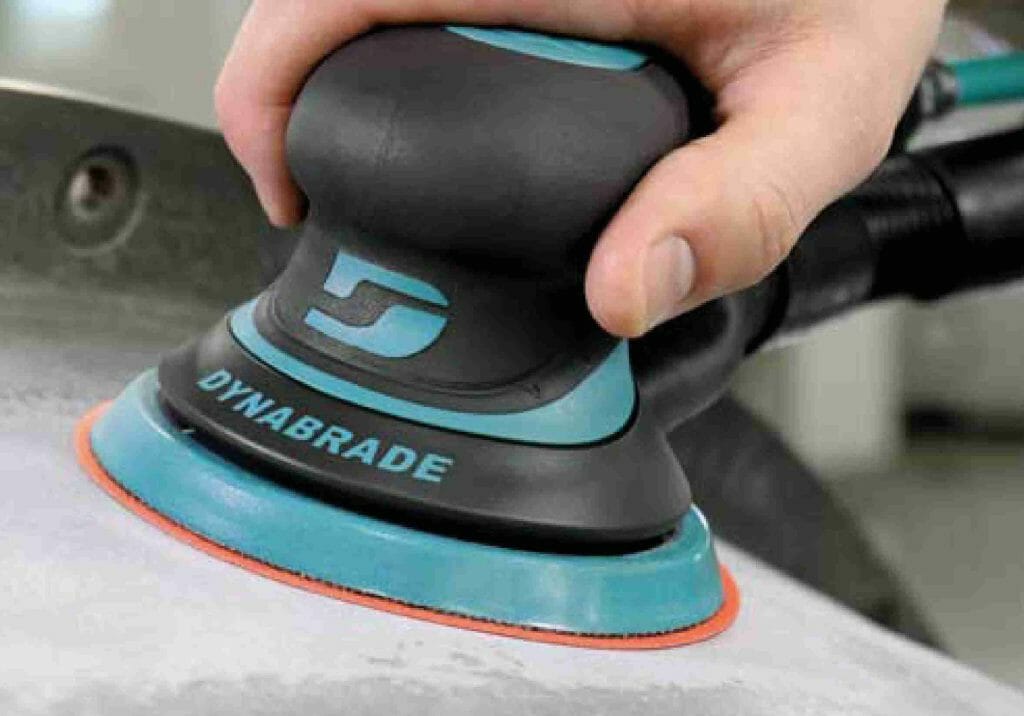

A pneumatic sander is a type of power sander that operates using compressed air as its power source. Pneumatic sanders are commonly used in auto body repair, woodworking, and metalworking applications.

They are typically more powerful than electric sanders and can handle heavier workloads. Pneumatic sanders come in various types, including belts, discs, and random orbital sanders.

What are the features of Pneumatic Sanders?

When choosing between pneumatic vs. electric random orbital sanders, they have some unique features that make them popular among professionals. Pneumatic sanders are powered by compressed air, which makes them more powerful and efficient than electric sanders.

In this section, we’ll explore some of the features of pneumatic sanders that set them apart from electric sanders.

1: Power and Performance:

Pneumatic sanders are known for their power and performance. They can handle heavy workloads and are ideal for sanding hard materials like metal, fiberglass, and hardwoods.

Because they are powered by compressed air, they have a consistent power output and can maintain a constant speed under heavy loads. This makes them ideal for sanding large surfaces or for extended periods.

2: Durability:

Pneumatic sanders are built to last. They have fewer moving parts than electric sanders, requiring less maintenance and a longer lifespan. Pneumatic sanders are also less likely to overheat or burn out, a common problem with electric sanders.

3: Versatility:

Pneumatic sanders are available in various sizes and shapes, making them versatile for various applications. They can sand flat surfaces, curved surfaces, and hard-to-reach areas. Random orbital sanders, in particular, are famous for their ability to produce a swirl-free finish on surfaces.

4: Noise and Vibration:

Pneumatic sanders are generally quieter and produce less vibration than electric sanders. This makes them more comfortable to use for extended periods and reduces the risk of hand fatigue or injury.

Advantages of Pneumatic Sanders

Choosing between pneumatic and electric random orbital sanders can be daunting for a customer. While both types of sanders have pros and cons, pneumatic sanders offer several advantages that may make them more appealing. This section will explore the advantages of pneumatic sanders over electric sanders.

1: More Power and Efficiency:

One of the most significant advantages of pneumatic sanders is their power and efficiency. Pneumatic sanders are powered by compressed air, which provides consistent power output and allows them to maintain a constant speed under heavy loads. This makes them ideal for sanding large surfaces or for extended periods.

2: Durability and Longevity:

Pneumatic sanders are also known for their durability and longevity. They have fewer moving parts than electric sanders, which means they require less maintenance and are less likely to break down or burn out. This means less time and money spent on repairs and replacements as a customer.

3: Versatility:

Pneumatic sanders are available in various sizes and shapes, making them versatile for various applications. They can sand flat surfaces, curved surfaces, and hard-to-reach areas. Random orbital sanders, in particular, are famous for their ability to produce a swirl-free finish on surfaces. As a customer, you can use one tool for multiple tasks, reducing the need to purchase multiple sanders.

4: Reduced Noise and Vibration:

Another advantage of pneumatic sanders is their reduced noise and vibration. Compared to electric sanders, pneumatic sanders produce less noise and vibration, making them more comfortable for extended periods. As a customer, this means reduced hand fatigue and a lower risk of injury.

5: Cost-Effective:

Lastly, pneumatic sanders are often more cost-effective than electric sanders. While the initial investment for a pneumatic sander may be higher due to the need for an air compressor, in the long run, pneumatic sanders require less maintenance and have a longer lifespan than electric sanders. This can save you money on repairs and replacements in the long run.

You can also check out our other related article How to use an orbital sander on cabinets like a pro?

Disadvantages of Pneumatic Sanders

As a customer, when considering pneumatic vs electric random orbital sanders, it’s important to understand the disadvantages of each type of sander. In this section, we’ll explore some of the disadvantages of pneumatic sanders.

1: Air Compressor Required:

One of the biggest disadvantages of pneumatic sanders is the need for an air compressor to power the tool. This means an additional upfront cost for purchasing an air compressor and the ongoing cost of operating the compressor. As a customer, this may not be a practical or cost-effective option if you don’t already have an air compressor.

2: Mobility:

Another disadvantage of pneumatic sanders is their need for more mobility. Since they require an air compressor to operate, they are tethered to the location of the compressor, which can limit their use in certain situations. This may be fine in a workshop or garage, but it could be a limitation for on-site or outdoor work.

3: Maintenance:

While pneumatic sanders require less maintenance than electric sanders, they still require regular maintenance to ensure proper operation. This includes oiling the tool, checking for leaks, and cleaning the air filter. As a customer, this means additional time and effort spent on maintenance.

4: Noise Level:

While pneumatic sanders are generally quieter than electric sanders, they still produce significant noise when in operation. As a customer, this may be a concern if you work in a noise-sensitive environment or need to use the tool for extended periods.

5: Initial Cost:

As mentioned earlier, while pneumatic sanders are often more cost-effective in the long run, the initial investment can be higher than electric sanders due to the need for an air compressor. As a customer, this may be a deciding factor in choosing between pneumatic vs electric random orbital sanders.

What are Electric Random Orbital Sanders?

Electric random orbital sanders are power tools that use electricity to rotate the sanding disk in a circular pattern while simultaneously moving it in an elliptical motion. This dual-action movement ensures that the sanding is performed evenly without leaving swirl marks on the sanded surface. Electric random orbital sanders are commonly used in woodworking and automotive applications for sanding and finishing surfaces.

Here are the features of Electric Random Orbital Sanders.

When it comes to sanding, electric random orbital sanders are a popular choice for both DIY enthusiasts and professionals. In this section, we’ll explore some of the key features of electric random orbital sanders.

1: Power:

Electric random orbital sanders are powered by electricity, which provides a consistent level of power for sanding. This means they can be used for extended periods without needing a break or a recharge, making them ideal for larger sanding projects. Additionally, electric random orbital sanders have variable speed controls, allowing you to adjust the speed of the sanding disk to match the task at hand.

2: Dual-Action Sanding:

Electric random orbital sanders use a dual-action sanding motion that ensures an even sanding finish without leaving swirl marks on the sanded surface. This is achieved by rotating the sanding disk in a circular pattern and moving it in an elliptical motion.

3: Dust Collection:

Electric random orbital sanders often come equipped with a dust collection system that helps keep the work area clean and debris-free. This is achieved by either a built-in dust collection bag or a dust port attached to a vacuum cleaner or dust extractor.

4: Versatility:

Electric random orbital sanders come in various sizes and designs, making them versatile tools that can be used for a wide range of sanding tasks. From small palm-sized sanders for detail work to larger, heavy-duty models for industrial use, there is an electric random orbital sander to suit every need.

5: Ease of Use:

Electric random orbital sanders are relatively easy to use, with ergonomic designs that help to reduce operator fatigue. They are also lightweight and maneuverable, idealizing tight spaces or extended periods.

Advantages of Electric Random Orbital Sanders

Electric random orbital sanders offer several advantages over pneumatic sanders. This section will explore some key advantages of electric random orbital sanders from a customer’s perspective.

1: Convenience:

One of the most significant advantages of electric random orbital sanders is their convenience. Unlike pneumatic sanders, which require an air compressor to operate, electric random orbital sanders can be used anywhere there is a power outlet. This makes them ideal for DIY enthusiasts needing access to an air compressor and for professionals who need to work on-site.

2: Ease of Use:

Electric random orbital sanders are relatively easy to use, with ergonomic designs that reduce operator fatigue. They are also lightweight and maneuverable, idealizing tight spaces or extended periods. This ease of use can improve results, as users are less likely to make mistakes or experience fatigue-related errors.

3: Versatility:

Electric random orbital sanders are available in various sizes and designs, making them suitable for various applications. From small palm-sized sanders for detail work to larger, heavy-duty models for industrial use, there is an electric random orbital sander to suit every need. This versatility allows users to tackle various sanding tasks with a single tool, reducing the need to invest in multiple sanders.

4: Control:

Electric random orbital sanders offer a high degree of control, allowing users to adjust the speed of the sanding disk to match the task at hand. This control can lead to better results, as users can better tailor the sanding process to the sanded material.

5: Dust Collection:

Electric random orbital sanders often come equipped with a dust collection system that helps keep the work area clean and debris-free. This can improve working conditions, reduce cleanup time, and provide a healthier work environment.

Disadvantages of Electric Random Orbital Sanders

While electric random orbital sanders offer several advantages over pneumatic sanders but also have disadvantages; in this section, we’ll explore some key disadvantages of electric random orbital sanders from a customer’s perspective.

1: Power Requirements:

One of the main disadvantages of electric random orbital sanders is their reliance on electricity. Unlike pneumatic sanders, which can be operated using an air compressor, electric sanders require a reliable power source. Users may need to invest in extension cords or portable power sources to use the sander in remote locations.

2: Cost:

Electric random orbital sanders are often more expensive than their pneumatic counterparts. This cost can be prohibitive for some users, especially those who only need the sander occasionally. In addition to the initial purchase price, electric sanders may require additional maintenance and repair costs over time.

3: Weight:

While electric random orbital sanders are often lightweight and easy to maneuver, some models can be heavier than pneumatic sanders. This added weight could make the sander more difficult to use for extended periods, especially for users with physical limitations.

4: Heat Build-Up:

Electric random orbital sanders can generate heat during use, which can be a disadvantage in some applications. For example, if the sander is used to sand a material sensitive to heat, such as plastic or certain types of wood, it can cause damage or deformation.

Here are the Similarities of Pneumatic vs. Electric Random Orbital Sanders

Regarding sanding tools, two of the most popular options on the market are pneumatic and electric random orbital sanders. While there are some differences between the two types of sanders, there are also several similarities. This section will explore key similarities between pneumatic and electric random orbital sanders from a customer’s perspective.

1: Orbital Motion:

Both pneumatic and electric random orbital sanders operate using a circular orbital motion. This motion is designed to ensure that the sanding disc moves in a random pattern, which helps to prevent swirl marks and other imperfections on the sanded surface.

2: Variable Speed:

Many pneumatic and electric random orbital sander models offer variable speed options. This allows users to adjust the sander’s speed to match the job’s requirements. For example, slower speeds may be necessary for sanding delicate materials, while faster speeds may be needed for more aggressive sanding.

3: Dust Collection:

Both pneumatic and electric random orbital sanders typically have dust collection systems to capture the dust and debris generated during sanding. This helps to keep the work area clean and reduces the risk of respiratory issues for the user.

4: Multiple Disc Sizes:

Pneumatic and electric random orbital sanders are available in multiple disc sizes, allowing users to choose the size that best fits their job requirements. Larger disc sizes are typically better suited for larger surfaces, while smaller ones are ideal for detail work or sanding in tight spaces.

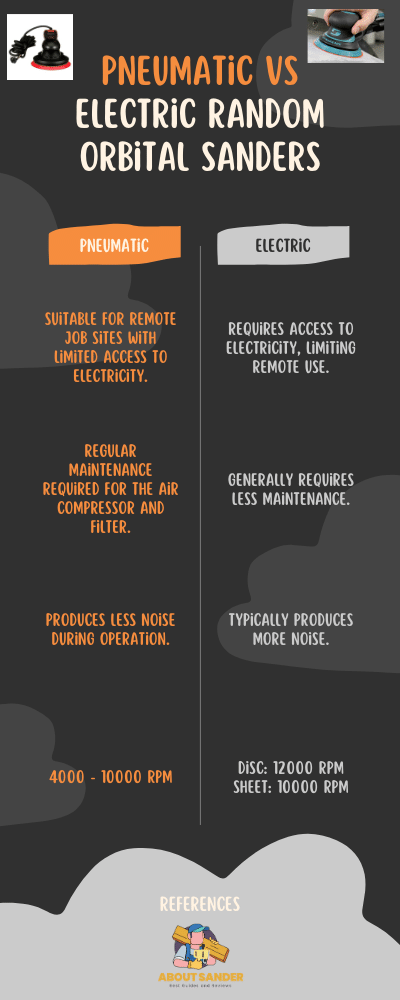

These are a few differences between Pneumatic Vs Electric Random Orbital Sanders.

As a customer looking for a sanding tool, it’s essential to understand the differences between pneumatic and electric random orbital sanders. While both types of sanders have similarities, there are also several differences. This section will explore key differences between pneumatic and electric random orbital sanders.

1: Power Source:

The power source is among the most significant differences between pneumatic and electric random orbital sanders. Pneumatic sanders are powered by compressed air, while electric sanders are powered by electricity. This means that pneumatic sanders require an air compressor, while electric sanders can be plugged into a standard electrical outlet.

2: Size and Weight:

Another difference when comparing pneumatic vs electric random orbital sanders is their size and weight. Pneumatic sanders are typically smaller and lighter than electric sanders, making them easier to maneuver and use for extended periods. However, this also means that pneumatic sanders may be less potent than electric sanders.

3: Noise Level:

Pneumatic sanders tend to be louder than electric sanders. This is because they require an air compressor to operate, which can generate a significant amount of noise. Electric sanders, on the other hand, are generally quieter in operation.

4: Cost:

Cost is another factor to consider when deciding between pneumatic vs electric random orbital sanders. Pneumatic sanders are generally less expensive than electric sanders, but they also require the purchase of an air compressor, which can be a significant investment. Electric sanders may have a higher initial cost but don’t require additional equipment.

5: Maintenance:

Pneumatic sanders require regular maintenance, including oiling and cleaning, to ensure that they operate properly. Electric sanders require less maintenance, but they may need to be serviced by a professional if they develop issues.

Conclusion:

Pneumatic sanders are more powerful and durable but require an air compressor and are louder. On the other hand, electric sanders are quieter, more portable, and require less maintenance, but they are more expensive and may not be as durable as their pneumatic counterparts. Choosing between Pneumatic vs. electric Random Orbital Sanders depends on your specific needs and preferences.

Why Trust About Sanders?

When it comes to the world of sanding and sanders, you need a trusted source of information and guidance to ensure you achieve those perfect finishes. That's where I come in – I'm Martin, a dedicated sanding enthusiast with a relentless passion for attaining flawless surfaces. With years of hands-on experience in the sanding industry, I've honed my skills and expertise to provide you with the most reliable and accurate insights. What sets me apart is my commitment to excellence. I meticulously handpick each sander after rigorous testing, ensuring that only the best tools make it to your hands. My goal is to empower you with the knowledge and recommendations you need to tackle any sanding task confidently. When you trust About Sanders, you're putting your faith in a seasoned expert who shares your passion for perfection and strives to deliver top-notch information and reviews for every sanding challenge.