Learn how to clean drum sander effectively with this detailed step-by-step guide. Discover essential tips and techniques to maintain your tool, ensuring optimal performance and extending lifespan. Perfect for woodworkers seeking to keep their drum sanders in peak condition.

Key Takeaways

- Avoid using water to clean sanding drum, as it may damage the adhesive on the sandpaper.

- Prioritize safety by powering off and unplugging the machine before cleaning and wear appropriate protective gear.

- Use a cleaning stick or block to remove residues from the sanding belt.

- Inspect the belt for damage and proper alignment during the cleaning process.

- Compressed air can be useful for blowing off remaining debris from the sanding belt.

- Store your drum sander belts in a clean and dry area when not in use to preserve their quality.

- Establish a maintenance schedule based on your woodworking project frequency for efficient cleaning and care.

How to Clean Drum Sander: A Step-by-Step Guide for Woodworkers

If you’re a passionate woodworker, you know the value of a well-maintained drum sander. This essential tool helps you achieve smooth and polished finishes on your projects, but regular cleaning is vital to keep it running at its best. Let’s dive in and discover how to maintain your drum sander to achieve exceptional results in your woodworking endeavors.

Step 1: Safety First: Power Off and Unplug

Before cleaning your drum sander, prioritize safety by turning off and unplugging the tool. This prevents accidental startup during the cleaning process, which could lead to injuries. Allow the drum sander to cool down if recently used to avoid burns.

Step 2: Empty Dust Collection System

Begin by emptying the dust collection system. Dust and debris can accumulate quickly and hinder your drum sander’s performance. Remove the dust collection bag or canister and dispose of the contents in a proper waste receptacle. Wipe down the interior of the collection area with a damp cloth to ensure it’s free from residual dust.

Step 3: Remove Excess Sawdust

Use a handheld brush or a vacuum cleaner with a soft brush attachment to remove excess sawdust from the drum sander’s exterior and hard-to-reach areas. Pay special attention to crevices and corners where debris can accumulate.

Step 4: Detach and Clean Sanding Drum

Carefully remove the sanding drum from the drum sander according to your machine’s user manual. Brush off any visible sawdust and debris from the drum’s surface. For thorough cleaning, use a mild solvent or mineral spirits on a clean cloth to remove stubborn residues.

Step 5: Clean the Conveyor Belt

Inspect the conveyor belt for sawdust buildup and residue. Clean it using a soft brush, a lint-free cloth dampened with water, or a mild cleaner. Avoid using harsh chemicals that could damage the conveyor belt material.

Step 6: Check and Clean Conveyor Rollers

Check the conveyor rollers for any dust or debris accumulation. Remove the rollers following the manufacturer’s instructions and clean them thoroughly. Use a brush and a cloth dampened with water or a suitable cleaner to ensure they’re free from buildup.

Step 7: Inspect and Clean Drum Sander Table

Examine the drum sander table for any lingering dust or particles. Wipe it down with a damp cloth or use compressed air to remove debris from hard-to-reach areas. Keeping the table clean is essential for achieving even and consistent sanding results.

Step 8: Lubricate Moving Parts

Apply a thin layer of lubricant to the moving parts of your drum sander, such as the drum support bearings and elevation mechanism. Lubrication reduces friction, ensuring smoother operation and prolonging the lifespan of these critical components.

Step 9: Reassemble and Test

After cleaning and lubricating, carefully reassemble all the components following the manufacturer’s instructions. Once assembled, perform a quick test run without any workpieces to ensure everything functions correctly.

Step 10: Regular Maintenance Schedule

To maintain your drum sander’s performance, establish a regular maintenance schedule. Depending on the frequency of use and workload, set aside time every few weeks or months for cleaning and inspection. Staying on top of maintenance will keep your drum sander in peak condition for all your future woodworking projects.

Top 10 Benefits of Cleaning Your Drum Sander

Cleaning your drum sander is more than just a chore; it’s an essential maintenance task that can significantly impact your woodworking projects’ quality and the longevity of your tool. A clean drum sander ensures optimal performance, smooth finishes, and a safer work environment.

1: Improved Sanding Performance

A clean drum sander operates at its best, providing improved sanding performance. By removing sawdust and debris that can hinder the sanding process, you’ll achieve smoother and more precise finishes on your woodwork.

2: Extended Drum Life

Regularly cleaning your drum sander can extend the life of the sanding drum. Sawdust and debris left on the drum can cause unnecessary wear and tear, potentially shortening its lifespan. A clean drum sander ensures even wear and efficient sanding, increasing its longevity.

3: Enhanced Dust Collection Efficiency

A clean drum sander contributes to better dust collection efficiency. When the dust collection system is free from clogs and blockages, it can effectively capture and contain airborne dust,

providing a cleaner and healthier work environment.

4: Safer Operation

Safety is paramount in woodworking, and cleaning your drum sander ensures a safer operation. Removing debris from the machine reduces the risk of accidental fires and improves safety during sanding tasks.

5: Consistent Sanding Results

Consistency is key in woodworking projects, and a clean drum sander helps deliver consistent sanding results. The sanding process is uniform without interfering with debris, avoiding irregularities and imperfections in your finished pieces.

6: Reduced Risk of Wood Contamination

Sawdust and debris can cling to the wood surface during sanding, potentially contaminating the material and causing blemishes on the finish. Keeping your drum sander clean minimizes the risk of wood contamination and ensures pristine results.

7: Efficient Material Removal

A clean drum sander efficiently removes material from your workpieces, saving time and effort. When the drum is free from buildup, it can easily tackle sanding tasks, resulting in quicker project completion.

8: Quieter Operation

A drum sander with accumulated debris may produce more noise during operation. Cleaning the drum reduces friction and noise levels, creating a quieter and more comfortable woodworking experience.

9: Prolonged Abrasive Life

A clean drum sander can prolong the life of the abrasive sandpaper. Debris can wear down sandpaper faster, making it less effective. With a clean drum, the sandpaper lasts longer, saving you money and reducing waste.

10: Professional-Level Finishes

Finally, cleaning your drum sander lets you achieve professional-level finishes on your woodworking projects. With a well-maintained machine, you’ll be confident to create masterpieces with smooth and flawless surfaces.

Factors to Consider When Cleaning Your Drum Sander

Cleaning your drum sander is essential to its maintenance routine, ensuring optimal performance and extending its lifespan. In this article, we’ll explore the key considerations to remember when undertaking this crucial task, empowering you to maintain your drum sander in peak condition for all your woodworking projects.

1: Read the Manufacturer’s Manual

Before cleaning your drum sander, consult the manufacturer’s manual. Each drum sander model might have specific cleaning instructions, safety precautions, and maintenance recommendations. Following the manual’s guidelines ensures you clean your machine correctly without risking damage.

2: Safety Precautions

Safety should always be a top priority when cleaning your drum sander. Make sure the machine is turned off and unplugged before you start. Allow the sander to cool down if recently used to avoid burns. Wearing safety gear like gloves and safety goggles is also recommended to protect yourself from dust and debris.

3: Choose the Right Cleaning Tools

Selecting the right cleaning tools is crucial to avoid damaging your drum sander. Soft-bristled brushes, lint-free cloths, and a vacuum cleaner with a brush attachment are excellent choices for removing dust and debris without scratching or harming the machine’s components.

4: Dust Collection System

Pay special attention to the dust collection system during the cleaning process. Empty the dust collection bag or canister regularly to maintain its efficiency. Ensure the collection area is completely clean before reassembling the components.

5: Lubrication

Cleaning your drum sander also provides an opportunity for lubrication. Check the manufacturer’s recommendations for lubricating moving parts, such as the drum support bearings and elevation mechanism. Using the appropriate lubricant will ensure smoother operation and prevent premature wear.

6: Thoroughness of Cleaning

Be thorough when cleaning your drum sander. Remove and clean the sanding drum properly, wiping off any stubborn residues. Clean the conveyor belt and rollers to ensure they are free from dust and debris. A thorough cleaning guarantees optimal performance and extends the life of your machine.

7: Frequency of Cleaning

The frequency of cleaning your drum sander depends on how often you use it and the intensity of your woodworking projects. If you use the sander frequently or handle large volumes of material, you should clean it more regularly. Establishing a maintenance schedule based on usage will help keep your drum sander in shape.

8: Working Environment

Consider your working environment when cleaning your drum sander. If your workspace is dusty or humid, you may need to clean the machine more often to prevent excessive dust buildup and potential damage to sensitive components.

9: Proper Disposal of Waste

Dispose of the collected sawdust and debris properly. Use a designated waste receptacle and avoid letting sawdust accumulate in your workshop, as it can be a fire hazard.

10: Inspecting for Damages

While cleaning your drum sander, please take the opportunity to inspect it for any damages or signs of wear. Identifying issues early can prevent further damage and save you from costly repairs down the line.

10 Bonus Tips to Clean Drum Sander

When it comes to maintaining your drum sander, a clean machine is key to achieving exceptional results in your woodworking projects. This article explores ten bonus tips to help you clean drum sander like a pro, ensuring optimal performance and extending lifespan.

1: Use Compressed Air for Dust Removal

Compressed air is an excellent tool for removing dust and debris from hard-to-reach areas of your drum sander. Attach a nozzle to your air compressor and carefully blow away the buildup from crevices and corners that are challenging to access with traditional cleaning tools.

2: Consider a Dust Deputy or Cyclone Separator

Consider adding a Dust Deputy or cyclone separator to enhance your dust collection system’s efficiency. These devices trap larger particles before they reach the dust collector, reducing the load on the primary filter and extending its life. A cleaner dust collection system means less maintenance and better overall dust removal.

3: Vacuum with HEPA Filter

If you suffer from allergies or want to ensure the cleanest working environment, use a vacuum cleaner with a HEPA filter. HEPA filters trap tiny particles and allergens, preventing them from being released back into the air.

4: Clean Sandpaper with Crepe Block

Extend the life of your sandpaper by cleaning it with a crepe block. Gently rub the crepe block over the sandpaper to remove embedded dust and debris. This trick helps maintain the sandpaper’s cutting ability, providing smoother sanding results.

5: Check and Adjust Conveyor Belt Alignment

During the cleaning process, take the opportunity to inspect the conveyor belt alignment. If necessary, adjust the alignment to ensure even and consistent material feeding. Proper alignment improves sanding results and prevents premature wear on the belt.

6: Use Denatured Alcohol for Stubborn Residues

For stubborn residues on the drum or conveyor belt, dampen a cloth with denatured alcohol and gently wipe the affected areas. Denatured alcohol effectively dissolves adhesive residues and sticky materials, making cleaning the drum and belt surfaces easier.

7: Protect Electrical Components

When cleaning your drum sander, be cautious around electrical components and switches. Avoid getting liquids or excessive dust near these sensitive parts, which could lead to electrical issues or malfunctions.

8: Inspect Sanding Drum for Wear

Look closely at the sanding drum for signs of wear or damage. If you notice uneven wear or nicks on the drum surface, it might be time to replace it. A well-maintained drum ensures consistent sanding performance.

9: Maintain a Clean Work Area

Keep your work area clean and organized to prevent excess dust and debris from settling on your drum sander. Regularly sweep or vacuum the floor and surrounding surfaces to minimize the dust that can get into your machine.

10: Keep Spare Parts and Cleaning Supplies on Hand

Stock up on spare parts, such as sanding drums and conveyor belts, to avoid downtime in case of unexpected wear or damage. Keep your cleaning supplies readily available, ensuring you can quickly tackle maintenance tasks when needed.

Here is the process to clean drum sander belts

Cleaning drum sander belts is crucial for maintaining their effectiveness and prolonging lifespan. Over time, sanding belts can accumulate sawdust, resin, and other debris that hinder their sanding performance. Follow this step-by-step process to clean drum sander belts effectively:

Step 1: Power Off and Unplug

Before cleaning, ensure the drum sander is powered off and unplugged to avoid any accidental startup and potential injuries.

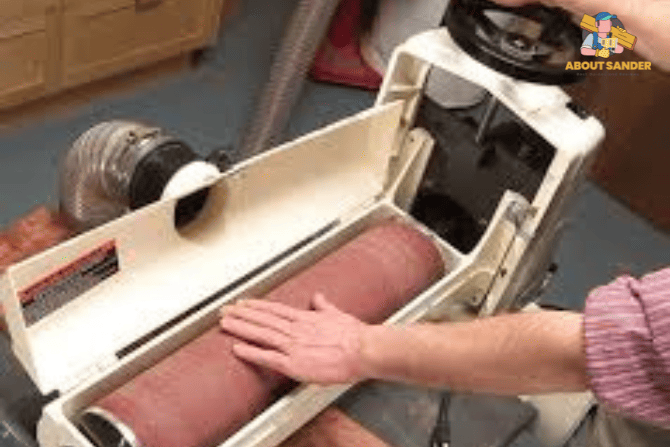

Step 2: Remove the Belt

Carefully remove the sanding belt from the drum sander. Follow your machine’s user manual for instructions on safely detaching and removing the belt.

Step 3: Inspect the Belt

Examine the sanding belt for any visible damage, wear, or clogging. If the belt is severely worn or damaged, it may be time to replace it instead of cleaning it.

Step 4: Use a Belt Cleaning Stick or Block

A belt cleaning stick or block is designed to remove residues from sanding belts. Lightly press the cleaning stick against the running sanding belt. The stick’s abrasive material will remove the accumulated sawdust and debris from the belt’s abrasive surface.

Step 5: Check Belt Tension and Alignment

While cleaning the belt, please take the opportunity to check its tension and alignment. Ensure the belt is properly tensioned and aligned for the best sanding results.

Step 6: Blow Off Remaining Residues

If some residues persist after using the cleaning stick, use compressed air to blow off the remaining debris from the sanding belt. Hold the closed air nozzle a few inches from the belt to

avoid damaging it.

Step 7: Reinstall the Belt

Once the sanding belt is clean, reattach it to the drum sander following the manufacturer’s instructions. Make sure the belt is correctly aligned and tensioned adequately for optimal performance.

Step 8: Test the Belt

After reinstalling the belt, perform a test run without any workpieces. Observe the belt’s performance to ensure it runs smoothly and evenly across the drum.

Step 9: Regular Maintenance

Cleaning your drum sander belt should be part of your regular maintenance routine. Depending on your usage frequency and the amount of debris generated, clean the belt after every few projects or as needed.

Step 10: Proper Storage

Store your drum sander belts in a clean and dry area when not in use. Avoid leaving them exposed to dust or humidity, as this can affect their performance over time.

FAQs

Got questions about cleaning your drum sander? We’ve got you covered! Here are three frequently asked questions and their concise answers to help you keep your drum sander in top shape.

1: How often should I clean drum sander?

It’s recommended to clean drum sander regularly, especially after heavy use or handling large amounts of material. Establish a maintenance schedule based on your woodworking projects’ frequency to ensure optimal performance and prolong the lifespan of your machine.

2: Can I use water to clean the sanding drum?

Water is generally not recommended to clean the sanding drum, as it can damage the adhesive bonding of the sandpaper to the drum. Instead, use a mild solvent or mineral spirits on a clean cloth to wipe away stubborn residues without compromising the sandpaper’s integrity.

3: What safety precautions should I take when cleaning my drum sander?

Safety is crucial when cleaning your drum sander. Always power off and unplug the machine before washing to prevent accidental startup. Wear safety goggles and gloves to protect yourself from dust and debris. Avoid getting liquids near electrical components and switches to prevent electrical issues.

Conclusion:

In conclusion, cleaning a drum sander is essential for maintaining its peak performance and longevity. Following the recommended steps and incorporating regular maintenance can achieve smoother sanding results and a safer woodworking environment.

Why Trust About Sanders?

When it comes to the world of sanding and sanders, you need a trusted source of information and guidance to ensure you achieve those perfect finishes. That's where I come in – I'm Martin, a dedicated sanding enthusiast with a relentless passion for attaining flawless surfaces. With years of hands-on experience in the sanding industry, I've honed my skills and expertise to provide you with the most reliable and accurate insights. What sets me apart is my commitment to excellence. I meticulously handpick each sander after rigorous testing, ensuring that only the best tools make it to your hands. My goal is to empower you with the knowledge and recommendations you need to tackle any sanding task confidently. When you trust About Sanders, you're putting your faith in a seasoned expert who shares your passion for perfection and strives to deliver top-notch information and reviews for every sanding challenge.