Do you need clarification about which woodworking tool to use for your next project? The drum sander vs. planer are two popular options that many woodworkers’ debates. So, let’s dive into the drum sander vs. planer world and discover which tool comes out on top.

Key Takeaways:

Here are some key takeaways from the comparison between Drum Sander vs. Planer:

- Drum sanders are ideal for quickly removing significant material, while planers are better for achieving specific thickness and width measurements.

- Drum sanders are great for smoothing surfaces, while planers are better for preparing wood for jointing or glue-ups.

- Both tools have their own pros and cons, and it is important to consider the project’s specific needs before choosing one.

- The cost of these tools varies, and investing in a high-quality tool that will last for years is important.

- Safety is important when using both tools, and it is important to read and follow the manufacturer’s instructions carefully.

- With proper use and maintenance, drum sanders and planers can be valuable additions to any woodworking shop.

What is Drum Sander?

A drum sander is a woodworking tool that uses a rotating sanding drum to smooth and finish large pieces of wood. It consists of a drum that holds a sanding belt or sleeve, which rotates rapidly and removes material from the surface of the wood.

| Serial No. | Features | Pros | Cons | Types |

| 1 | Smoothing Capabilities | Provides smooth finish on large pieces of wood. | Not suitable for precise sanding. | Open-end drum sanders, Closed-end drum sanders. |

| 2 | Fast Material Removal | Capable of removing large amounts of material in a short time. | Generates a lot of dust and noise. | Stationary drum sanders, Portable drum sanders |

| 3 | Multiple Grit Options | Offers the option to use different grits for different jobs. | Requires frequent belt replacements. | Benchtop drum sanders, Floor drum sanders |

| 4 | Large Sanding Surface | Able to accommodate large pieces of wood for sanding. | Can be expensive to purchase and maintain. | Drum flap sander, Combination drum/belt sander |

| 5 | Versatility | Can be used to sand a variety of materials, not just wood. | Requires more frequent cleaning and maintenance than others. | Thickness sanders, Spindle sanders, Edge sanders, etc. |

How does a drum sander work?

Drum sander vs. planer – when it comes to woodworking, the debate over these two popular tools is endless. While a planer is used for thickness, a drum sander is a finishing tool to achieve a smooth surface on a board. But how does a drum sander work?

Step 1: Adjusting the Feed Rate

Before you start sanding, adjust the feed rate of the drum sander to the appropriate speed. The feed rate controls how quickly the board is fed through the machine, and a slower feed rate will produce a finer finish.

Step 2: Sanding the First Pass

Start by sanding the first pass of the board through the drum sander. Use coarse-grit sandpaper and ensure the board is level and straight as it passes through the machine.

Step 3: Sanding the Second Pass

After the first pass, switch to finer-grit sandpaper and make a second pass through the drum sander. This will remove any remaining roughness and produce a smooth surface on the board.

Step 4: Repeating the Process

Depending on the size and thickness of the board, you may need to repeat the sanding process several times, gradually increasing the grit of the sandpaper until you achieve the desired finish.

Step 5: Cleaning the Board

Once you’ve finished sanding, vacuum, or compressed air to clean the board and remove any dust or debris, drum sanders are an effective tool for achieving a smooth and even surface on large pieces of wood.

3 Features of Drum Sander

Drum sander vs. planer – two essential tools in woodworking that serve different purposes. A drum sander is a finishing tool that produces a smooth and even surface on a board, whereas a planer is used for thickness. As an expert in this field, I can confidently tell you that a drum sander is essential for achieving a high-quality finish on your woodworking projects.

1: Large Sanding Drum

One of the most significant features of a drum sander is its large sanding drum. The drum is usually between 4-6 inches in diameter and rotates rapidly to remove material from the surface of the wood. A larger drum means that you can sand larger pieces of wood, which is useful for finishing large slabs or panels.

2: Adjustable Feed Rate

Another feature of a drum sander is its adjustable feed rate. The feed rate controls how quickly the board is fed through the machine, and a slower feed rate produces a finer finish. This feature allows you to adjust the machine to your desired finish, making it a versatile tool for different woodworking projects.

3: Multiple Grit Sandpaper

Drum sander vs, planer can use multiple grits of sandpaper, making them a versatile tool for different finishing levels. You can start with coarse-grit sandpaper and gradually work up to finer-grit sandpaper until you achieve the desired finish. This feature makes a drum sander useful for both rough and finished sanding.

Pros of a Drum Sander

Drum sander vs. planer is powerful and versatile tools that can be used to finish a wide range of woodworking projects. As an expert in this field, I can confidently tell you that there are several advantages to using a drum sander over other sanding methods, such as hand sanding or a planer. This article will explore the top five pros of using a drum sander in your woodworking projects.

1: Produces a Consistent Finish

One of the most significant advantages of a drum sander is that it produces a consistent finish across the entire surface of the board. The sanding drum rotates at high speed, ensuring the sandpaper removes an even amount of material from the surface.

2: Saves Time

A drum sander can save you significant time compared to other sanding methods. The sanding drum can remove material quickly, allowing you to finish large projects in a fraction of the time it would take with hand sanding. Additionally, the adjustable feed rate allows you to adjust the machine’s speed to your desired finish, saving you time.

3: Versatility

Drum sander vs. planer incredibly versatile tools that can be used for various sanding tasks. Depending on the grit of the sandpaper used, they can be used to remove material quickly or achieve a fine finish. They are also useful for sanding curved surfaces like chair legs or arms.

Cons of Drum Sander

As an expert in woodworking, I can attest that while drum sanders have many benefits, there are also some drawbacks to using this tool. In this article, we will explore the top five cons of using a drum sander in your woodworking projects to help you decide whether a drum sander or planer is right for your needs.

1: Expensive

One of the biggest drawbacks of drum sanders is their cost. Drum sander vs. planer can be quite expensive compared to other sanding methods, such as hand sanding or a planer. The price of a drum sander can range from a few hundred to several thousand dollars, making it a significant investment for most woodworkers.

2: Limited Width Capacity

Drum sanders are limited in the width of the boards they can sand. Most drum sanders have a maximum width capacity of around 24 inches, which can be limiting for larger projects. A planner may be a better option if you frequently work with wider boards.

3: Creates More Dust

While drum sanders have a dust collection system, they still create significant sawdust. This dust can be messy and pose a health hazard if improperly collected and disposed of. Regular cleaning of the workspace and dust collection system is essential to maintain a safe and healthy environment.

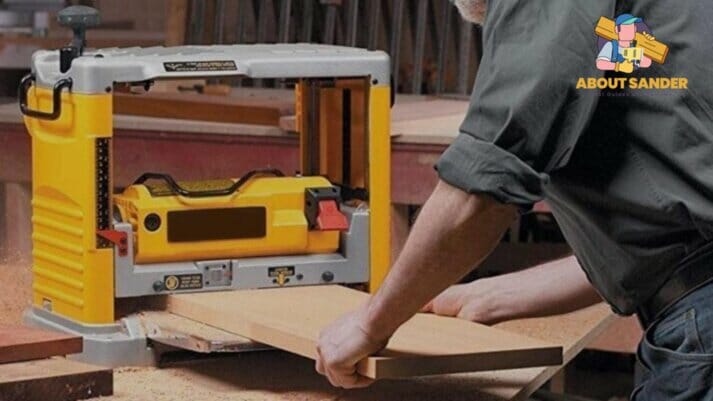

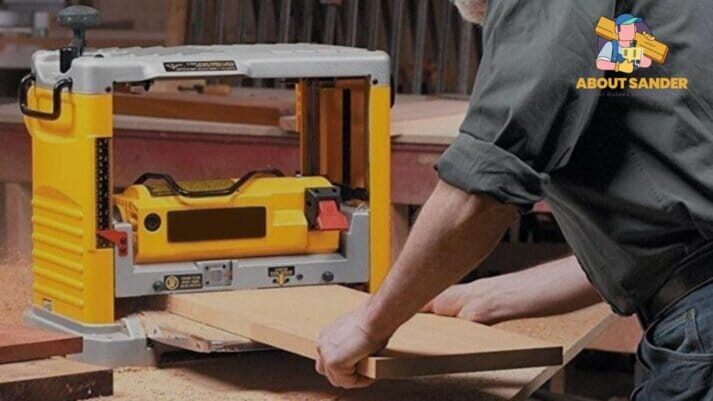

What is Planer?

A planer is a woodworking machine used to flatten and smooth the surface of rough lumber or to reduce the thickness of boards to a uniform size. Planers are commonly used in furniture making, cabinetry, and construction to create flat and uniform surfaces for different woodworking processes.

| Serial No. | Features | Pros | Cons | Types |

| 1 | Efficiency | Smooth and fast performance | Can produce snipe at the ends of the board | Handheld, Benchtop, Thickness planer, Jointer-Planer combo |

| 2 | Versatility | Can handle large pieces of wood | Limited to straightening boards and cannot create curves | Handheld, Benchtop, Thickness planer, Jointer-Planer combo |

| 3 | Precision | Accurate and consistent results | Limited to one dimension only | Handheld, Benchtop, Thickness planer, Jointer-Planer combo |

| 4 | Depth control | Ability to adjust the depth of cut | Can be noisy and produce a lot of dust | Handheld, Benchtop, Thickness planer, Jointer-Planer combo |

| 5 | Speed | Can remove large amounts of material quickly | Requires careful setup and maintenance | Handheld, Benchtop, Thickness planer, Jointer-Planer combo |

Here are steps to elaborate on how does planer work?

If you’re a woodworking enthusiast, you likely know that a planer is a key tool for creating smooth, flat surfaces on boards. But how does it work? In this article, we’ll break down the steps involved in using a planer, and explore the key differences between a planer and a drum sander.

1: Preparation

Before using a planner, it’s important to prepare the board. Remove any nails or screws and ensure the board is free of debris. Also, check the board for any warping or bowing, as these defects can cause problems during planning.

2: Adjustments

The next step is to adjust the planer to the desired thickness. Most planers have a knob that allows you to adjust the cutting depth of the blades. Making small adjustments to remove only a little wood in a single pass is important.

3: Feed the Board

Now it’s time to feed the board into the planer. Hold the board firmly against the infeed rollers and press the power switch to turn on the machine. The rollers will grab the board and pull it through the planer while the spinning blades shave off a thin layer of wood from the surface.

4: Repeat as Necessary

Once the board has been planned on one side, flip it over and repeat the process on the other side. Continue flipping and planning until the board is smooth and flat on both sides. Finally, you can finish the board with sandpaper or a drum sander to achieve the desired smoothness and surface quality.

3 Features of a Planer

As an expert in woodworking, a planer is an essential tool for any woodworker. Whether working on a large construction project or a small furniture piece, a planer can help you achieve a smooth and uniform surface. In this article, we’ll explore the top five features of a planer that make it a must-have tool for any woodworking project.

1: Thickness Adjustment

One of the most significant advantages of using a planer is its ability to adjust the thickness of the wood. A thickness planer can quickly and accurately remove material from the surface of the wood to create a uniform thickness throughout the board. This feature is crucial for creating flat, uniform surfaces for many woodworking projects.

2: Variable Feed Rate

Most modern planers come with a variable feed rate feature, which allows you to adjust the speed at which the wood is fed into the planer. This feature is essential for creating a smooth and even finish, especially when working with different types of wood. Adjusting the feed rate ensures that the wood is not damaged or burned during the planning process.

3: Dust Collection System

A planer produces a significant amount of sawdust and debris during use. To keep your workspace clean and safe, many planers have a dust collection system that removes the dust and debris from the machine. This feature is essential for maintaining a healthy and safe working environment.

Pros of Planer

When it comes to woodworking, a planer is a powerful tool that can provide numerous benefits. As an expert in this field, I know that a planner can help you achieve a smooth and even finish, increase efficiency, and save time and effort. This article will explore the top five pros of using a planer for your woodworking projects.

1: Saves Time and Effort

A planer can quickly and accurately remove material from the surface of the wood, making it an efficient tool for reducing the thickness of rough lumber and creating flat and uniform surfaces. This feature can save you significant time and effort, allowing you to complete your projects more quickly and with less physical strain.

2: Achieves a Smooth and Uniform Surface

One of the most significant advantages of using a planer is its ability to create a smooth and even finish on the wood. The precision cutting head and variable feed rate feature allow you to achieve a consistent thickness and surface texture, giving your projects a professional and polished appearance.

3: Increases Efficiency

With a planer, you can quickly and accurately reduce the thickness of rough lumber or create flat and uniform surfaces. This increased efficiency can help you complete your woodworking projects faster and with less waste, saving you time and money in the long run.

Cons of the Planer

As an expert in woodworking, I know that while a planner can provide many benefits, it also has some downsides. This article will explore the top five cons of using a planer for your woodworking projects.

1: Expensive

A planner can be expensive, especially for hobbyists or those just starting in woodworking. High-end models can cost several thousand dollars, making it a significant investment that may only be practical for some.

2: Noise and Dust

Planers are notorious for their noise and dust levels. The loud whirring of the motor and the high-speed blades can create a loud noise level, while the dust created by the process can be hazardous to your health if inhaled. Appropriate safety measures, such as ear protection and a dust mask, should be taken when using a planer.

3: Requires Skill and Experience

A planner requires skill and experience to use properly. In inexperienced hands, a planer can be dangerous and cause injury. Additionally, improper use can damage the wood or create uneven surfaces.

Drum Sander vs. Planer

| Feature | Drum Sander | Planer |

| Type of tool | Sanding machine | Cutting machine |

| Primary function | Sanding wood or other materials to a smooth finish | Planing wood to a specific thickness and width |

| Sanding capabilities | Can smooth surfaces and remove material quickly | Limited to smoothing and minor material removal |

| Material capacity | Can handle larger materials like tabletops | Limited to smaller pieces of wood |

| Dust collection | Effective dust collection systems available | Dust collection system can be less effective |

| Noise level | Can be loud, especially with larger machines | Can be quieter than drum sanders, especially benchtop models. |

| Blade maintenance | No blades to sharpen or replace | Blades need to be sharpened or replaced periodically. |

| Cost | Generally more expensive than planers | Generally less expensive than drum sanders |

| Versatility | Can be used for sanding a variety of materials | Limited to planing wood |

| Final product quality | Can produce a very smooth finish on wood | Produces a very precise and consistent thickness. |

| Skill level required | Can be used by novice or professional woodworkers | Can be more challenging for novice woodworkers. |

Comparison of Drum Sander vs. Planer

When it comes to woodworking, there are a lot of different tools and techniques that you can use to achieve your desired results. The drum sander and the planer are two of the most popular tools for smoothing and flattening boards. This article will compare drum sanders and planers in 10 key areas.

1: Surface Finish

One of the biggest differences between drum sanders and planers is the surface finish they produce. Planers are great for creating smooth, flat surfaces, while drum sanders are better suited for creating contoured or curved surfaces. Planers leave a smooth surface with straight, parallel lines, while drum sanders produce a smoother, rounded surface.

2: Speed

Another important consideration is speed. Planers can quickly remove a lot of material, making them ideal for larger projects where time is of the essence. On the other hand, drum sanders tend to be slower but produce a more even finish.

3: Accuracy

When it comes to accuracy, planners are the clear winner. They are designed to create precise cuts to a specific thickness, making them ideal for creating uniform boards. Drum sander vs. planer, on the other hand, can be more difficult to control and may produce uneven results.

4: Dust Collection

Drum sander vs. planer produce a lot of dust and debris, so it’s important to have a good dust collection system. Planers tend to produce larger chips and shavings that are easier to collect, while drum sanders produce finer dust that can be more difficult to capture.

5: Versatility

While both tools are great for smoothing and flattening boards, they have different strengths when it comes to versatility. Planers are great for creating uniform boards but may struggle with curved or irregular surfaces. On the other hand, Drum sander vs. planer are better suited for creating contoured or curved surfaces but may be less effective on flat boards.

6: Cost

Cost is another important consideration when choosing between a drum sander and a planer. Planers are more affordable, with entry-level models starting at a few hundred dollars. Drum sander vs. planer can be quite expensive, with high-end models costing several thousand dollars.

7: Maintenance

Both drum sander vs. planer requires regular maintenance to keep them in good working order. Planers require periodic blade changes and adjustments to cut at the correct depth. Drum sanders may require periodic sandpaper changes and cleaning of the sanding drum.

8: Noise

Another consideration when choosing between a drum sander and a planer is noise. Both tools can be loud, but drum sanders are slightly quieter than planers.

9: Safety

As with any woodworking tool, safety is paramount. Both drum sanders and planers can be dangerous if not used properly, so following all safety guidelines and wearing appropriate protective gear is important.

10: Project Type

Ultimately, the choice between a drum sander and a planer will depend on the type of project you’re working on. A planer is likely the best choice if you need to create flat, uniform boards. A drum sander may be the better option if you need to create curved or contoured surfaces.

FAQs

Here are FAQs on Drum Sander vs. Planer:

1: What is the main difference between a drum sander and a planer?

The primary difference between a drum sander and a planer is their function. A drum sander is a sanding machine used to smooth surfaces and remove material quickly, while a planer is a cutting machine used to plane wood to a specific thickness and width.

2: Which tool is better for preparing a piece of wood for finishing: a drum sander or a planer?

It depends on the specific needs of the project. If you need to smooth the surface of the wood and remove a significant amount of material, a drum sander is the better choice. If you need to plane the wood to a specific thickness and width, a planer is better.

3: Can a drum sander be used as a planer or vice versa?

While a drum sander and a planer may seem similar, they are not interchangeable. A drum sander is not designed to plane wood, and a planer is not designed for sanding wood. Attempting to use one tool for the function of the other can damage the tool and poor results on the project.

4: Can you use a drum sander as a planer?

No, a drum sander cannot be used as a planer. They serve different purposes and have different mechanisms.

5: Can a drum sander flatten a board?

Yes, a drum sander can flatten a board to some extent, but it is primarily designed for sanding and not as effective as a dedicated planer for heavy material removal.

Conclusion

In conclusion, the drum sander vs. planer are useful tools for woodworking, but they have different functions and are designed to be used in different ways. A drum sander is ideal for quickly smoothing surfaces and removing significant material, while a planer is better for achieving specific thickness and width measurements.

Why Trust About Sanders?

When it comes to the world of sanding and sanders, you need a trusted source of information and guidance to ensure you achieve those perfect finishes. That's where I come in – I'm Martin, a dedicated sanding enthusiast with a relentless passion for attaining flawless surfaces. With years of hands-on experience in the sanding industry, I've honed my skills and expertise to provide you with the most reliable and accurate insights. What sets me apart is my commitment to excellence. I meticulously handpick each sander after rigorous testing, ensuring that only the best tools make it to your hands. My goal is to empower you with the knowledge and recommendations you need to tackle any sanding task confidently. When you trust About Sanders, you're putting your faith in a seasoned expert who shares your passion for perfection and strives to deliver top-notch information and reviews for every sanding challenge.