Regarding woodworking, two indispensable power tools often find themselves at the center of the debate: the belt sander vs planer. Both tools serve unique purposes in the woodworking process, each with advantages and applications.

While the belt sander excels at smoothing and shaping wood surfaces, the planer specializes in achieving precise thickness and parallelism.

Key Takeaways:

- Belt sanders excel in material removal and surface smoothing, while planers specialize in achieving precise thickness and parallelism.

- Belt sanders offer versatility and efficiency, making them ideal for shaping, smoothing, and removing imperfections.

- Planers provide accuracy in thickness control and create flat, even surfaces, making them essential for dimensioning lumber and achieving uniform results.

- Both tools have their place in woodworking, and the choice between them depends on the project’s specific needs.

- Consider the scale of the project, desired finish, and efficiency requirements when deciding whether to use a belt sander vs planer.

| Features | Belt Sander | Planer |

| Material Removal | Efficient | Limited |

| Surface Smoothing | Excellent | Limited |

| Thickness Control | Adjustable speed | Accurate depth |

| Edge Straightening | Limited | Excellent |

| Versatility | Wide range of tasks | Limited tasks |

| Dust Collection | Vacuum attachment | Dust collection port |

| Precision | Variable | High precision |

| Cost | Affordable | Higher cost |

| Space Efficiency | Compact | Larger footprint |

What do you need to know about Belt Sander?

A belt sander is a power tool used in woodworking for sanding and smoothing wood surfaces. It consists of a motor-driven sanding belt that moves in a continuous loop over two parallel rollers. The sanding belt, typically made of abrasive material, rotates rapidly, allowing for efficient material removal and surface leveling.

Exploring the Benefits of a Belt Sander

When it comes to woodworking, having the right tools can make all the difference. One such tool that stands out for its versatility and efficiency is the belt sander. This article will delve into six key advantages of using a belt sander, shedding light on why woodworking enthusiasts and professionals favor it.

1: Efficient Material Removal and Leveling:

One of the primary benefits of a belt sander is its ability to remove material quickly and efficiently. Equipped with a motor-driven sanding belt, it effortlessly smooths rough surfaces, eliminating imperfections and leveling uneven areas. Whether you’re dealing with rough lumber or need to remove old paint or varnish, the belt sander is a formidable tool, saving you time and effort compared to manual methods like hand planers.

2: Versatile Sanding Capabilities:

The belt sander vs planer offers remarkable versatility, from heavy material removal to fine finishing. With varying grit options, you can easily adapt the sanding belt to suit your woodworking needs. Whether you need to smooth large surfaces, shape curved edges, or tackle intricate detailing, the belt sander provides a wide range of sanding capabilities. It offers a level of precision that hand planers cannot match.

3: Effective in Removing Paint and Varnish:

If you’re working on a project that requires removing layers of paint or varnish from wood surfaces, the belt sander vs planer is an ideal choice. Its powerful motor and abrasive sanding belt effortlessly strip away old finishes, saving you from tedious scraping or using chemicals. Simply guiding the belt sander over the painted or varnished surface can achieve a clean and smooth base for refinishing or applying new coatings.

4: Compatibility with Vacuum Attachments:

One notable advantage of modern belt sanders is their compatibility with vacuum attachments. These attachments effectively capture the dust generated during sanding, ensuring a cleaner and healthier working environment. Reducing airborne dust particles not only does it improve visibility but also minimizes the risk of respiratory issues associated with prolonged exposure. This feature makes the belt sander vs planer with a vacuum attachment a practical choice for professional workshops and home woodworking spaces.

5: Ease of Use and Control:

Even for beginners, operating a belt sander vs planer is relatively straightforward. The handheld design allows easy maneuverability and control, ensuring precise sanding results. You can tailor the sanding process to suit the specific wood species and desired finish with adjustable speed settings. Additionally, many belt sanders feature ergonomic handles and comfortable grips, reducing fatigue during extended use.

6: Cost-Effective Solution:

Compared to other power tools, belt sanders are often more affordable, making them a cost-effective choice for woodworking enthusiasts. Their versatility and efficiency eliminate the need for multiple specialized tools, saving both money and storage space. Additionally, belt sanders require minimal maintenance, adding to their long-term value and cost-effectiveness.

In the belt sander vs planer debate, the belt sander emerges as a powerhouse of efficiency, versatility, and cost-effectiveness. Its ability to remove material quickly, tackle various sanding tasks, and provide exceptional control makes it a top choice for woodworkers of all skill levels.

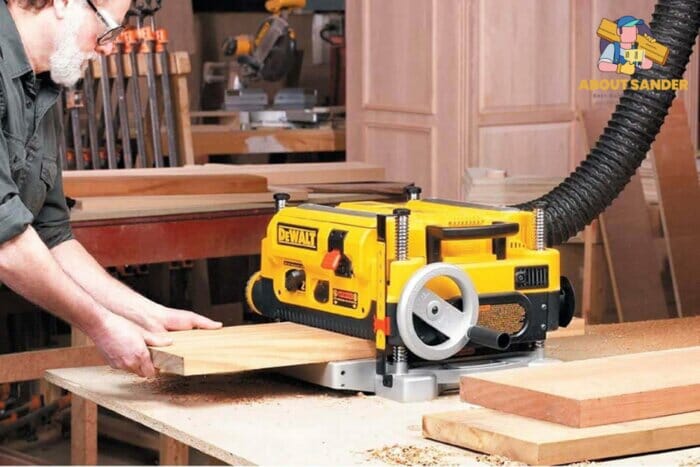

Unveiling the Planer: Achieving Precise Wood Thickness and Parallelism

A planer is a vital woodworking tool designed to achieve precise thickness and parallelism in wooden surfaces. It features a flat, rotating cutterhead with multiple cutting blades that remove material consistently and uniformly. As wood passes through the planer, the blades shave off thin layers, resulting in a smooth and even surface.

Exploring the Benefits of a Planer

In woodworking, achieving precise thickness and parallelism in wooden surfaces is crucial for impeccable craftsmanship. This is where the planer, a powerful woodworking tool, comes into play. In this article, we will delve into six key benefits of using a planer, shedding light on why it’s favored by woodworking enthusiasts and professionals seeking accuracy and uniformity in their projects.

1: Consistent Thickness and Parallelism:

The primary advantage of a planer lies in its ability to achieve consistent thickness and parallelism in wooden surfaces. By feeding the wood through the planer, the rotating cutterhead, equipped with multiple cutting blades, shaves off thin layers of material. This process ensures uniform thickness across the entire surface, eliminating irregularities and creating a smooth, level result.

2: Efficient Material Removal:

A planer is an efficient tool when you need to remove a specific amount of material from a wooden surface. With its precise depth adjustment capabilities, you can easily control the amount of material to be removed, achieving the desired thickness.

3: Perfectly Straight Edges and Jointing Surfaces:

Achieving straight and perfectly aligned edges is essential in woodworking, especially for joinery tasks. A planer excels in creating smooth, straight edges, making it ideal for producing clean jointing surfaces. You can effortlessly create precise edges by bypassing the wood through the planer, ensuring seamless joints and optimal fit.

4: Surface Preparation for Finishing:

Before applying finishes like paint, varnish, or stain, proper surface preparation is crucial for optimal results. A planer plays a significant role in this process by providing a smooth and uniform surface for finishing. By eliminating imperfections, such as scratches, gouges, or unevenness, the planer ensures an even application of finishes, enhancing the overall aesthetic appeal of the project.

5: Time and Labor Efficiency:

A planer significantly increases efficiency when dimensioning large quantities of lumber or working on extensive woodworking projects. Its ability to remove material uniformly and quickly saves considerable time and effort compared to manual methods. With each pass through the planer, you can achieve substantial progress, ensuring timely completion of projects and increased productivity.

6: Professional-Grade Precision:

For woodworking professionals, the planer offers precision essential for achieving professional-grade results. Whether you’re crafting fine furniture, intricate moldings, or high-quality cabinetry, the planer allows you to meet the demanding standards of craftsmanship, ensuring exceptional quality in every project.

In the ongoing debate of planer vs belt sander, the planer emerges as an indispensable tool for achieving precision, uniformity, and efficiency in woodworking. Its ability to deliver consistent thickness, straight edges, and surface preparation for finishing sets it apart as a go-to tool for woodworking enthusiasts and professionals.

Belt Sander vs Planer: Understanding the Key Differences in Woodworking

Choosing the right tools is essential to achieve desired results when it comes to woodworking. Understanding the key differences between these two power tools is crucial in the ongoing debate of belt sander vs planer. In this article, we will explore six notable differences between belt sanders and planers, shedding light on their functions, applications, and strengths to help you make an informed decision based on your woodworking needs.

1: Material Removal vs Surface Smoothing:

One of the fundamental differences between belt sanders and planers lies in their primary functions. A belt sander is designed to remove material, efficiently level rough surfaces, and shape wood. On the other hand, a planer focuses on achieving precise thickness and parallelism in wooden surfaces.

2: The versatility of Sanding Applications:

In terms of versatility, belt sanders offer a broader range of sanding applications than planers. Belt sanders can tackle various tasks with different grit options, from heavy material removal to fine finishing. They are suitable for smoothing large surfaces, shaping curved edges, and intricate detailing.

3: Precision in Thickness Control:

Planers take the lead when it comes to achieving precise thickness control. They offer accurate depth adjustment mechanisms that allow woodworkers to control the amount of material to be removed. While adjustable in speed, Belt sanders need more precision in thickness control than planers offer.

4: Jointing and Edge Straightening:

Creating straight and perfectly aligned edges is critical for woodworking, especially for joinery tasks. In this aspect, planers excel. They produce smooth, straight edges, making them ideal for creating joint surfaces. A planer is the preferred choice in scenarios where jointing and edge straightening are priorities.

5: Surface Preparation for Finishing:

Both tools offer benefits in different contexts when it comes to surface preparation for finishing. Belt sanders are excellent for prepping surfaces by removing old finishes, such as paint or varnish. While they can achieve a smooth finish, their primary purpose is thickness control and leveling rather than removing finishes.

6: Cost and Space Considerations:

When considering cost and space considerations, belt sanders are often more affordable and compact than planers. They also offer versatility, eliminating the need for multiple specialized tools. While essential for specific tasks, planers can be pricier and occupy more workshop space.

Belt Sander vs Planer: Exploring the Common Ground in Woodworking

In the world of woodworking, having the right tools is essential for achieving desired results. When comparing a belt sander vs a planer, while they possess unique characteristics, it’s worth noting that these tools also share certain similarities. Recognizing these commonalities can help woodworkers understand how they can complement each other in different aspects of woodworking.

1: Power and Motorized Operation:

This motorized operation provides the tools with the necessary power and speed to perform their respective functions effectively. Whether it’s driving the sanding belt of a belt sander or rotating the cutting blades of a planer, the motorized operation ensures efficient material removal and surface leveling in woodworking tasks.

2: Efficiency in Material Removal:

Efficient material removal is a shared characteristic of both belt sander vs planer. While their methods may differ, they are designed to remove material quickly and effectively. Belt sanders accomplish this by utilizing an abrasive sanding belt that rotates rapidly, while planers achieve material removal through a rotating cutterhead with multiple cutting blades.

3: Versatility in Woodworking Applications:

Belt sander vs planer offer versatility in woodworking applications, albeit in different aspects. Belt sanders are renowned for their ability to tackle a wide range of sanding tasks, from heavy material removal to fine finishing. They can be used on wooden surfaces, including large panels, curved edges, and intricate details.

4: Precision and Control:

Precision and control are crucial factors in achieving desired woodworking results, and both belt sanders and planers offer features that contribute to this aspect. With adjustable speed settings, Belt sanders allow users to tailor the sanding process to their specific needs, resulting in more controlled material removal and surface smoothing.

5: Dust Collection and Cleanup:

Woodworking generates a significant amount of dust, and both belt sanders and planers address this issue by offering dust collection capabilities. Many belt sanders come with vacuum attachments or built-in dust ports, allowing for efficient dust extraction during the sanding process. Similarly, planers often feature dust collection ports, which can be connected to dust extraction systems or vacuum cleaners.

6: Time and Labor Efficiency:

Both belt sanders and planers contribute to time and labor efficiency in woodworking tasks. Their power and efficiency in material removal allow woodworkers to accomplish projects more quickly than manual methods. With each pass of the belt sander vs planer, significant progress can be made, saving time and effort.

FAQs:

As woodworkers explore the differences and applications of belt sanders and planers, several common questions often arise. In this section, we address five frequently asked questions (FAQs) regarding belt sanders and planers, providing concise answers to help clarify key aspects of these woodworking tools.

1. Can a belt sander be used as a planer?

No, a belt sander cannot function as a planer. While both tools serve different purposes, a planer is specifically designed for achieving precise thickness and parallelism in wooden surfaces. At the same time, a belt sander is primarily used for material removal and surface smoothing.

2. Can a planer replace a belt sander?

While a planer and a belt sander have overlapping functions, they are not direct replacements for each other. A planer is ideal for achieving uniform thickness and leveling surfaces, while a belt sander excels in material removal, smoothing, and shaping. Depending on the woodworking task, both tools may be necessary to achieve desired results.

3. Can I use a handheld belt sander for large projects?

Yes, handheld belt sanders can be used for larger projects. However, they may require more time and effort due to their smaller size and limited surface coverage compared to larger stationary belt sanders. Consider the scale of your project and the efficiency required before choosing the appropriate belt sander.

4. Do planers create smooth surfaces?

Planers are primarily used for thickness and leveling surfaces rather than creating a smooth finish. While planers can leave a relatively smooth surface, they may still require additional sanding or finishing to achieve the desired level of smoothness.

5. Can I use a vacuum attachment with a belt sander?

Yes, many belt sanders can attach a vacuum or have built-in dust ports for dust collection. This feature helps minimize airborne dust particles, keeps the workspace cleaner, and improves visibility during sanding. A vacuum attachment with a belt sander is recommended for a more efficient and healthier working environment.

Conclusion

In conclusion, when comparing belt sanders vs planers, it is important to consider their distinct functions and applications in woodworking. Belt sanders excel in material removal and surface smoothing, offering versatility and efficiency. On the other hand, planers specialize in achieving precise thickness and parallelism, ensuring uniformity in wooden surfaces.

Why Trust About Sanders?

When it comes to the world of sanding and sanders, you need a trusted source of information and guidance to ensure you achieve those perfect finishes. That's where I come in – I'm Martin, a dedicated sanding enthusiast with a relentless passion for attaining flawless surfaces. With years of hands-on experience in the sanding industry, I've honed my skills and expertise to provide you with the most reliable and accurate insights. What sets me apart is my commitment to excellence. I meticulously handpick each sander after rigorous testing, ensuring that only the best tools make it to your hands. My goal is to empower you with the knowledge and recommendations you need to tackle any sanding task confidently. When you trust About Sanders, you're putting your faith in a seasoned expert who shares your passion for perfection and strives to deliver top-notch information and reviews for every sanding challenge.