What is a disc sander? Learn about this powerful woodworking tool and its various applications. Discover tips and techniques for using a disc sander effectively. Get all the insights you need to master your woodworking projects. Find out what a disc sander is. Its functions and how it fits into woodworking projects. Unlock the potential of this essential tool now!

Key Takeaways

- Disc sanders are powerful and versatile woodworking tools used to smooth and shape various materials efficiently.

- The disc sander’s key components include a sturdy base, a motor assembly, a sanding disc attachment, an on/off switch with speed control, and a dust collection system.

- To use a disc sander effectively, secure the material on the sander’s table, initiate the sanding process with proper hand placement, and achieve the desired smoothness through progressive grits or passes.

- Disc sanders have diverse applications, including woodworking, metalworking, automotive repairs, construction, and DIY projects.

- There are different types of disc sanders, such as benchtop, floor standing, combination disc and belt, oscillating, and handheld, each with unique features and use cases

How Do Disc Sanders Work? Here are 8 steps to understand:

Disc sanders are powerful and versatile woodworking tools that can quickly and efficiently smooth and shape various materials. Whether you’re a professional woodworker or a DIY enthusiast, understanding how a disc sander works is crucial to harnessing its full potential.

Step 1: The Base and Motor Assembly

The foundation of a disc sander is its sturdy base and motor assembly. The motor powers the rotating disc, while the bottom keeps the tool stable during operation. High-quality disc sanders boast robust construction to ensure smooth and vibration-free performance.

Step 2: Sanding Disc Attachment

A sanding disc is firmly attached to the rotating plate, allowing for effortless material removal. The disc’s diameter determines the sanding area and influences the speed at which the material is sanded. Interchangeable sanding discs with varying grits can be used to achieve different levels of smoothness.

Step 3: On/Off Switch and Speed Control

Modern disc sanders come equipped with an easy-to-access on/off switch and speed control dial. Once the tool is plugged in, users can activate the disc by flipping the switch. Adjusting the speed control allows for precise sanding, catering to different materials and project requirements.

Step 4: Dust Collection System

Efficient dust collection is a vital feature of disc sanders. As the sanding process generates considerable dust, a built-in dust collection system prevents debris from spreading and maintains a clean working environment. Some models include a dust bag or connect to an external vacuum for enhanced dust extraction.

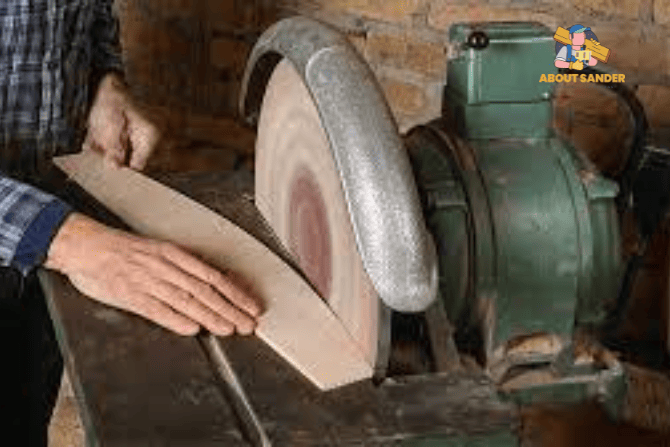

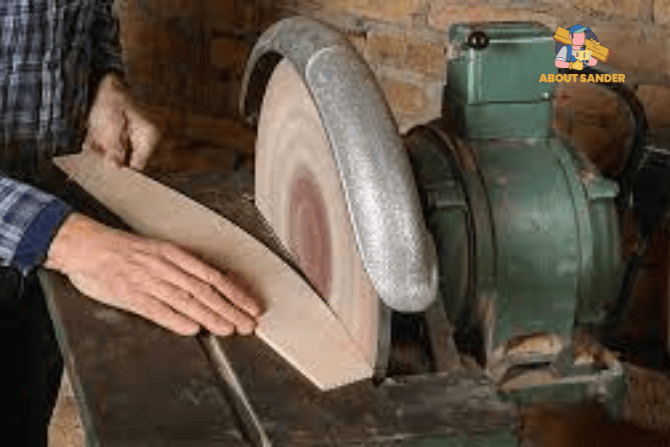

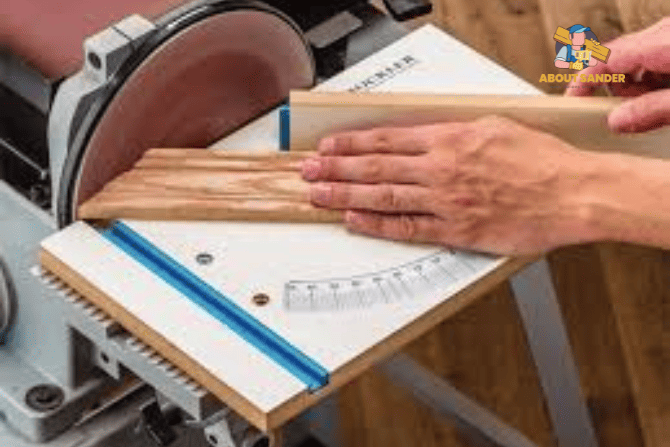

Step 5: Placing and Securing the Material

To begin sanding, position the material firmly against the rotating disc. The sander’s table provides a stable platform for accurate sanding. Some disc sanders also come with adjustable tables, enabling bevel sanding and angle adjustments for more intricate tasks.

Step 6: Initiating the Sanding Process

Once the material is securely placed, turn on the disc sander and let it reach the desired speed. Begin sanding by gently guiding the material towards the spinning disc, ensuring even and consistent contact across the surface. Exercise caution and maintain proper hand placement during the process.

Step 7: Achieving Desired Smoothness

Through progressive grits or gradual passes, the disc sander efficiently smooths the material’s surface. The operator can determine the level of smoothness required for the project. Regularly inspect the workpiece to monitor progress and make adjustments as needed.

Step 8: Safety and Aftercare

After completing the sanding process, turn off the disc sander and wait for the disc to come to a complete stop before unplugging the tool. Practice proper safety measures, such as wearing safety goggles and using a dust mask to protect against debris inhalation. Additionally, clean the disc and surrounding area to maintain the sander’s efficiency and longevity.

Exploring the Versatility of Disc Sanders:

Disc sanders are indispensable power tools widely used in various industries and applications. Their efficiency, precision, and versatility make them popular among woodworking professionals, metalworkers, automotive technicians, construction workers, and DIY enthusiasts alike.

1: Woodworking:

In the realm of woodworking, disc sanders are essential for both professional carpenters and hobbyist woodworkers. They excel in smoothing and shaping wooden surfaces, from removing rough stock to achieving finely finished edges. Whether a large furniture project or intricate wooden art, a disc sander is crucial in creating smooth, polished, uniform surfaces. Woodworkers use disc sanders to:

- Flatten rough wood surfaces

- Shape and bevel edges for a seamless finish

- Create consistent curves and contours on woodworking projects

- Refinish and prepare wooden furniture for painting or staining

2: Metalworking:

Disc sanders find their place in metalworking, particularly in preparing metal surfaces and achieving precise finishes. Metalworkers use disc sanders to remove burrs, sharp edges, and weld marks from metal workpieces. They are also employed to grind and smooth metal surfaces in preparation for further finishing processes.

Disc sanders can handle various metals, including steel, aluminum, and stainless steel, contributing to producing metal components with exceptional precision and quality.

3: Automotive:

The automotive industry benefits from the efficiency and speed of disc sanders for multiple applications. Auto body technicians use these tools to perform tasks such as:

- Removing rust and old paint from car panels

- Smoothing body filler and other repair materials

- Preparing surfaces before applying new paint or coatings

- Restoring headlights by sanding away haze and scratches

5: Construction:

Disc sanders are vital in construction projects, contributing to the preparation and finishing stages. In construction applications, disc sanders are used for tasks like:

- Smoothing wooden surfaces in carpentry projects

- Preparing drywall surfaces before painting or wallpapering

- Removing excess material and sharp edges from construction materials

- Refinishing wooden floors and decks

6: DIY/Home Improvement:

Disc sanders are invaluable tools for DIY enthusiasts and home improvement projects that save time and effort. They offer a wide range of applications for various tasks around the house, including:

- Sanding wooden furniture and surfaces for refinishing

- Smoothing rough edges on DIY woodworking projects

- Preparing surfaces for painting or staining

- Removing old paint, varnish, or adhesives from surfaces

A Comprehensive Guide to the Different Types of Disc Sanders:

As an expert in the field of woodworking, it’s essential to have a thorough understanding of the various tools at your disposal. The disc sander is among the most versatile and efficient power tools, which plays a crucial role in achieving smooth surfaces and precise shaping.

1: Benchtop Disc Sander

A benchtop disc sander is a stationary power tool designed to sit atop a workbench or sturdy surface. It consists of a flat sanding disc mounted on a spindle, with the disc rotating vertically. The machine is ideal for smaller projects and workshops with limited space.

Key Features:

- Compact and space-saving design

- Suitable for light to moderate sanding tasks

- Often equipped with tilting tables for bevel sanding

- Portable for on-the-go woodworking tasks

Ideal Use Cases:

- Smoothing edges and curves

- Shaping small workpieces

- Refinishing furniture

2: Floor Standing Disc Sander:

A floor-standing disc sander is a larger, more robust version of the benchtop model. It features a sturdy stand, vertical sanding disc, and powerful motor. This type of disc sander is commonly found in professional woodworking shops.

Key Features:

- Heavy-duty construction for stability and durability

- Powerful motor for intensive sanding tasks

- Greater sanding disc diameter for larger workpieces

- Equipped with adjustable tables and fences for precision sanding.

Ideal Use Cases:

- Smoothing large wooden panels

- Preparing wooden flooring

- Manufacturing custom woodworking pieces

3: Combination Disc and Belt Sander

A combination disc and belt sander combine disc and belt sanding capabilities in one machine. It typically features a sanding disc mounted on one side and a sanding belt on the other, offering users more options for different sanding tasks.

Key Features:

- Two-in-one design for added versatility.

- Adjustable worktables for both disc and belt sanding

- Suitable for various sanding angles and bevels

- Ideal for projects requiring different sanding techniques.

Ideal Use Cases:

- Smoothing irregular-shaped workpieces

- Beveling and chamfering edges

- Sharpening blades and tools

4: Oscillating Disc Sander

An oscillating disc sander features a sanding disc that moves in an orbital pattern, combining the advantages of both rotary and orbital sanders. This unique motion prevents swirl marks and delivers a smoother finish.

Key Features:

- Orbital motion for superior sanding results

- Reduced risk of overheating or gouging

- Dust collection capabilities for a cleaner workspace

- Suitable for delicate materials

Ideal Use Cases:

- Sanding veneers and delicate surfaces

- Fine finishing applications

- Achieving smooth contours on curved surfaces

5: Handheld Disc Sander

A handheld disc sander is a portable power tool for more flexible sanding operations. It is typically smaller and lighter than stationary disc sanders, making it suitable for on-site or remote woodworking tasks.

Key Features:

- Compact and easy to carry around.

- Corded or cordless options for convenience

- Suitable for sanding in tight or hard-to-reach areas

- It may have variable speed settings for versatility.

Ideal Use Cases:

- Refinishing wooden floors

- Sanding irregular-shaped objects

- Small-scale woodworking projects on the go

Understanding the different types of disc sanders is crucial for selecting the right tool that aligns with your woodworking requirements. Each class offers unique advantages, making them suitable for various projects and tasks.

The Advantages of Using a Disc Sander:

A disc sander is a fundamental tool in woodworking, valued for its efficiency and versatility. A flat

sanding disc rotating at high speeds can quickly smooth surfaces and shape materials with precision. As an expert in the field, understanding why to use a disc sander is essential for harnessing its full potential.

1: Efficient Material Removal:

A primary reason to use a disc sander is its exceptional material removal capabilities. The spinning sanding disc can rapidly shave away unwanted material, saving time and effort compared to manual sanding techniques. Whether you need to flatten rough wood surfaces or remove old finishes, a disc sander can tackle these tasks efficiently.

2: Precision Sanding:

Disc sanders offer precise sanding results, making them indispensable for achieving smooth and uniform surfaces. The spinning disc enables consistent contact with the material, preventing uneven sanding and leaving behind a polished finish. This level of precision is crucial for professional woodworking projects.

3: Versatility in Sanding:

A disc sander can handle various sanding tasks, from rough sanding to fine finishing. You can adapt the sander to suit various materials and surface requirements by selecting different grit sandpaper discs. A disc sander is up to the challenge, whether it’s hardwood, softwood, metal,

or even plastic.

4: Shaping and Beveling:

Beyond its sanding capabilities, a disc sander excels at shaping and beveling edges. The rotating disc and adjustable tables allow for precise angle adjustments and bevel sanding. This feature is precious for creating intricate designs and chamfers on woodworking projects.

5: Time-Saving Tool:

In a professional woodworking environment, time is of the essence. A disc sander’s rapid material removal and smooth sanding action significantly reduce project completion times. It enables woodworkers to accomplish more in less time, boosting overall productivity and efficiency.

6: Effective on Curved Surfaces:

Curved surfaces can be challenging to sand evenly, but a disc sander simplifies the process. The rotating disc conforms to the contours of curved workpieces, ensuring consistent sanding across the entire surface. This capability is particularly beneficial when working with curved furniture components or artistic pieces.

7: Dust Collection for a Clean Workspace:

Many disc sanders come equipped with dust collection systems, keeping the workspace clean and dust-free. Effective dust collection improves visibility and safety and reduces the need for time-consuming cleanup after sanding sessions.

8: Consistent Results for Batch Work:

When working on multiple identical pieces, achieving consistency is vital. A disc sander provides uniform results across all workpieces, ensuring a professional and polished look for batch projects. This advantage is valuable for producing furniture components or woodworking products in bulk.

9: Ideal for DIY and Hobbyist Woodworkers:

While professionals benefit from a disc sander’s efficiency, DIY enthusiasts and hobbyist woodworkers can reap its rewards. Its ease of use and ability to handle various sanding tasks make it accessible to woodworkers of all skill levels.

10: Precursor to Finer Sanding:

Before proceeding to finer sanding with handheld sanders, a disc sander can quickly remove significant imperfections and rough surfaces. Starting with a disc sander creates a smoother foundation for subsequent sanding, resulting in better-finished products.

The advantages of using a disc sander in woodworking are numerous and significant. From efficient material removal and precision sanding to its versatility and ability to handle curved surfaces, a disc sander is an invaluable tool for professionals and hobbyist woodworkers.

Understanding the Limitations of a Disc Sander:

As a woodworking expert, it’s essential to recognize that while a disc sander is a valuable tool with numerous advantages, it also has limitations. Understanding these limitations is crucial for ensuring safe and effective usage of the tool.

1: Limited Accessibility:

One notable limitation of a disc sander is its restricted accessibility. The sanding disc is fixed vertically, making reaching certain areas challenging or sanding intricate details on workpieces. This limitation is particularly evident when dealing with irregularly shaped objects or intricately designed furniture components.

2: Risk of Material Damage:

If not used with care and precision, a disc sander can pose a risk of material damage. The high rotational speed of the sanding disc, combined with the tool’s powerful motor, can lead to over-sanding or gouging of the material surface. This risk is especially pertinent when working with softer woods or delicate materials.

3: Limited Dust Collection Efficiency:

Although many disc sanders have built-in dust collection systems, their effectiveness may vary. Some models may need to efficiently capture all the dust and debris generated during sanding, leading to a dusty and messy workspace. Woodworkers must take additional precautions, such as wearing dust masks and using separate dust collection systems, to ensure a clean and safe environment.

4: Not Ideal for Finishing:

While a disc sander is excellent for material removal and initial smoothing, there may be better choices for finishing tasks. The spinning disc’s aggressive action can leave swirl marks or scratches on the material surface, requiring additional fine sanding with other tools like hand sanders or random orbital sanders.

5: Risk of Uneven Sanding on Curved Surfaces:

While a disc sander can handle curved surfaces, sanding on such contours can be challenging. If not properly guided, the rotating disc may create uneven surfaces or dips on the curvature, requiring extra care and skill from the operator.

6: Generates Noise and Vibration:

Disc sanders can be quite noisy during operation due to the high-speed rotation of the sanding disc and the vibrations produced by the motor. Extended use of the sander can lead to fatigue and discomfort for the operator. Wearing appropriate hearing protection and taking regular

breaks can help mitigate these issues.

7: Requires Adequate Workspace:

The size and design of a disc sander necessitate adequate workspace to accommodate the tool

and perform sanding tasks effectively. Finding a suitable space to set up the sander and maneuver larger workpieces for smaller workshops or compact working areas might pose a challenge.

8: Not Suitable for All Materials:

While disc sanders excel at woodworking tasks, they may only be suitable for some materials. Metals, plastics, and other non-wood materials can be challenging to sand effectively with a disc sander, potentially causing damage to the sanding disc or producing undesirable results.

Disc Sander Maintenance Tips: How to Keep Your Disc Sander Performing at Its Best

As a woodworking expert or DIY enthusiast, ensuring the proper maintenance of your disc sander is essential for optimal performance and longevity. This guide will provide expert tips on maintaining your disc sander, ensuring it remains in top-notch condition for all your sanding projects.

1: Regular Cleaning of Dust and Debris:

Dust and debris are common byproducts of sanding, and they can accumulate quickly inside the disc sander, affecting its performance and potentially leading to premature wear. Regularly clean the dust collection system, dust ports, and surrounding areas to prevent clogging and ensure efficient dust extraction.

2: Inspection and Replacement of Sanding Discs:

Examine the sanding disc before each use to ensure it is free from cracks, tears, or excessive wear. Damaged or worn-out sanding discs can result in uneven sanding and may pose a safety risk. Replace any damaged or worn discs promptly with new ones of the appropriate grit to maintain optimal sanding performance.

3: Lubrication of Moving Parts:

A well-lubricated disc sander operates smoothly and reduces friction, enhancing its efficiency. Check the manufacturer’s guidelines for recommended lubricants and apply them to the moving parts, such as bearings and drive shafts, at regular intervals.

4: Adjustment and Alignment:

Periodically inspect and adjust the alignment of the sanding disc and the sander’s tables. Misalignment can result in uneven sanding and reduce the tool’s effectiveness. Ensure that the sanding disc is parallel to the table surface and that the tables are square to the disc to achieve precise and consistent sanding results.

5: Cleaning or Replacing Filters:

If your disc sander has a built-in dust collection system with filters, check these filters regularly and clean or replace them as needed. Clogged or dirty filters can impede dust collection, leading to a dusty workspace and potentially affecting the sander’s performance.

6: Inspecting the Power Cord:

Examine your disc sander’s power cord and plug for signs of damage, such as cuts, fraying, or exposed wires. A damaged power cord can be hazardous and should be replaced immediately. Always unplug the sander from the power source before inspecting or performing any maintenance.

7: Proper Storage:

When not in use, store your disc sander in a dry and clean environment. Please protect it from dust, moisture, and extreme temperatures, which can damage the motor and other components. Consider covering the sander with a dust cover or storing it in a dedicated tool cabinet to maintain its pristine condition.

8: Regular Inspection and Maintenance by a Professional:

While the user can perform some maintenance tasks, it is essential to schedule regular inspections and maintenance by a qualified professional. Professional servicing can address potential issues that may not be evident during regular user maintenance, ensuring the disc sander operates at its peak performance.

FAQs About What Is a Disc Sander?

Disc sanders are versatile power tools used in various industries and DIY projects. As with any tool, it’s natural to have questions about its usage and features. This section addresses some frequently asked questions (FAQs) about disc sanders to provide you with essential information and guidance.

1. What is a disc sander used for?

A disc sander is primarily used for smoothing and shaping various materials, such as wood, metal, and plastic. It efficiently removes excess material, sharp edges, and old finishes, leaving behind a polished and uniform surface. Its versatility makes it a valuable tool for woodworking, metalworking, automotive repairs, construction, and DIY projects.

2. How does a disc sander differ from other sanders?

Unlike other sanders, a disc sander features a rotating sanding disc that operates in a vertical plane. This design allows for efficient material removal and precise sanding. Other sanders, such as belt or random orbital sanders, have different sanding mechanisms and may be better suited for specific tasks.

3. Are disc sanders suitable for beginners?

Beginners can use disc sanders, but it’s essential to approach them with caution. Their powerful motor and rapid sanding action require proper handling and safety measures. Beginners should familiarize themselves with the tool’s functions, wear appropriate safety gear, and practice scrap material before tackling actual projects.

Conclusion:

A disc sander is a powerful tool for smoothing and shaping materials like wood, metal, and plastic. It efficiently removes excess material and leaves behind a polished surface. Whether you are a beginner or an experienced woodworker, understanding “What is a disc sander” and how to use it properly is essential for woodworking, metalworking, automotive repairs, construction, and DIY projects.

Why Trust About Sanders?

When it comes to the world of sanding and sanders, you need a trusted source of information and guidance to ensure you achieve those perfect finishes. That's where I come in – I'm Martin, a dedicated sanding enthusiast with a relentless passion for attaining flawless surfaces. With years of hands-on experience in the sanding industry, I've honed my skills and expertise to provide you with the most reliable and accurate insights. What sets me apart is my commitment to excellence. I meticulously handpick each sander after rigorous testing, ensuring that only the best tools make it to your hands. My goal is to empower you with the knowledge and recommendations you need to tackle any sanding task confidently. When you trust About Sanders, you're putting your faith in a seasoned expert who shares your passion for perfection and strives to deliver top-notch information and reviews for every sanding challenge.